RADSOK®

Contact:

Description:

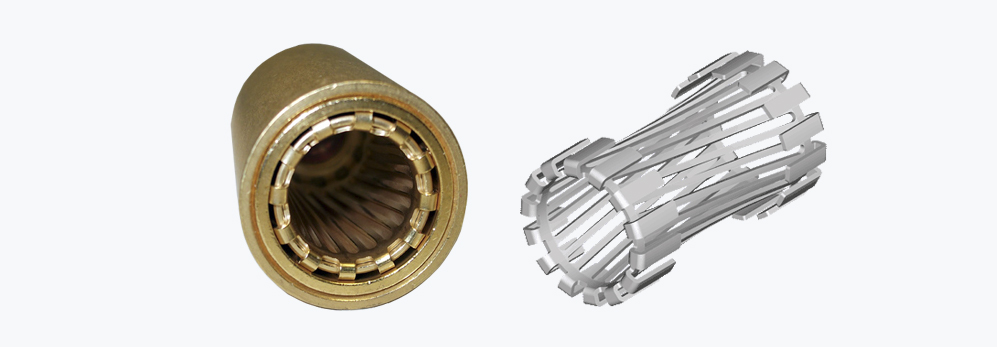

RADSOK® technology is based upon a stamped and formed flat grid, uniquely twisted into a hyperbolic geometry to provide robust, high-density contact to the mating pin contact. Most pin and socket technologies rely upon spring (beam element) properties of the contact elements, which tend to weaken over time. Unlike most other pin and socket solutions, the RADSOK® also utilizes the tensile strength properties of the flat, high conductivity alloy grid. This provides the high normal forces required for conductivity while also providing a large conductive surface area. A corresponding low voltage drop and low-temperature rise are also achieved while maintaining low insertion forces.

Features & Benefits:

Low Contact Engagement/Separation Forces:

- The hyperbolic lamella socket contact construction distributes normal forces over a high percentage of mating pin surface. This creates a smooth, even engagement effort. This force distribution also contributes to excellent performance in vibration applications with resistance to typical fretting corrosion.

Low Contact Resistance:

- The large interface area between the socket lamella and pin surface results in very low contact resistance, enabling the RADSOK® contacts’ high current rating compared to traditional power contact designs.

High Mating Cycle Durability:

- RADSOK® contacts with typical silver plating finishes have demonstratable of 20,000 mating cycles. Even with continuous exposure to harsh environmental abuse and corrosive elements like salt, sand, and high humidity. RADSOK® contacts have been tested to maintain low contact resistance beyond 10,000 mating cycles.

Availability:

- RADSOK® contacts are available throughout the Amphenol connector catalog in hundreds of product lines in industrial, automotive, medical, and other industries.

Low Contact Engagement/Separation Forces:

The hyperbolic lamella socket contact construction distributes normal forces over a high percentage of mating pin surface. This creates a smooth, even engagement effort. This force distribution also contributes to excellent performance in vibration applications with resistance to typical fretting corrosion.

Low Contact Resistance:

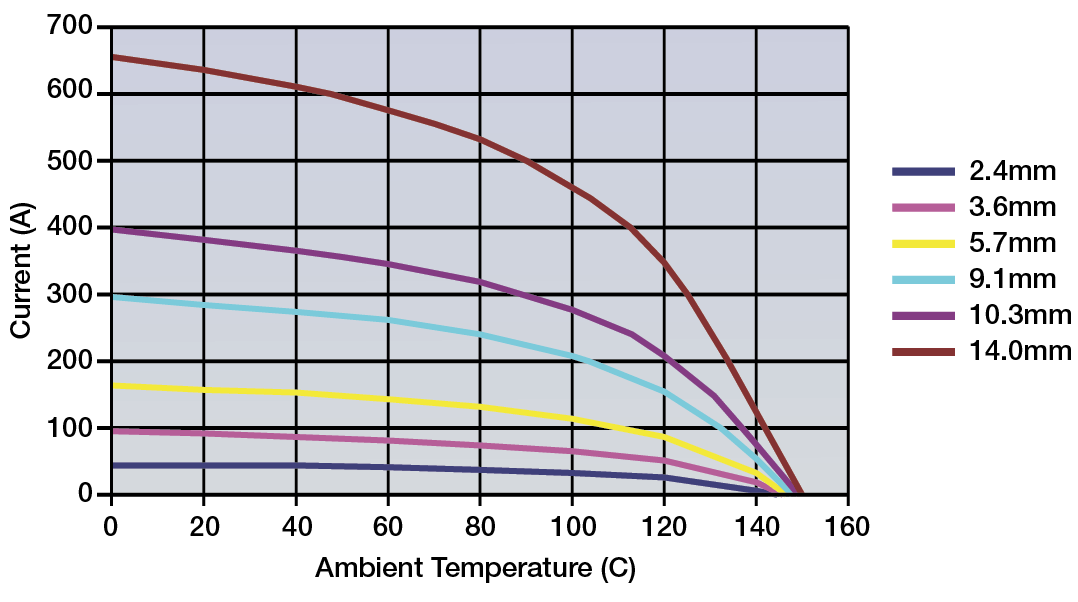

The large interface area between the socket lamella and pin surface results in very low contact resistance, enabling the RADSOK® contacts’ high current rating compared to traditional power contact designs.

High Mating Cycle Durability:

RADSOK contacts with typical silver plating finishes have demonstrated the survival of 20,000 mating cycles. Even with continuous exposure to harsh environmental abuse (salt, sand, and high humidity). RADSOK contacts have been tested to maintain low contact resistance beyond 10,000 mating cycles.

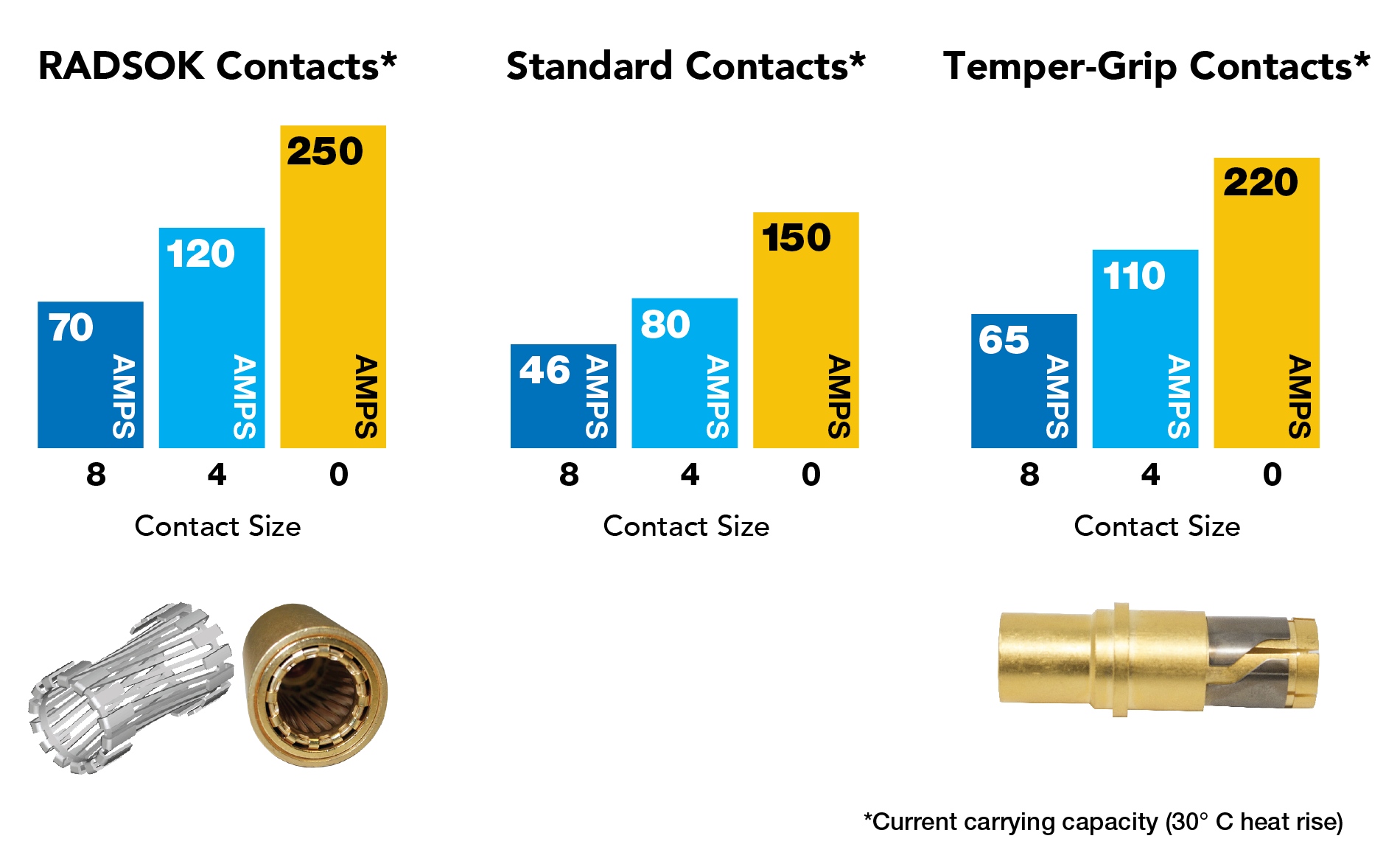

| Standard Contacts | RADSOK Contacts | ||||

| Size | Amps | Size | Amps | Cartridge Size | |

| 8 | 46 | 8 | 70 | 3.6mm | |

| 4 | 80 | 4 | 120 | 5.7mm | |

| 0 | 150 | 0 | 250 | 9.1mm | |