Pyle MIL-DTL-83723 Circular Connectors

Contact:

Description:

The Amphenol MIL-DTL-83723 Series III family of connectors includes styles from Pyle National. These have proven technology for severe environments and are widely used in commercial and military aerospace markets. Amphenol/Pyle 83723 connectors incorporate many advantageous features, such as a unique threaded coupling mechanism that provides greater resistance to decoupling. This coupling mechanism eliminates the need for safety wiring and tends to couple during vibration - thus offering the user added assurance and a margin of safety.

Amphenol/Pyle 83723 Series III high-temperature styles are capable of operation at 500 °F (260 °C). A 100% scoop-proof version of the high-temperature connector is also available under specification ESC11/Pyle HTK Series. In addition, this connector series incorporates a unique sealing grommet that is capable of sealing on standard diameter wire as well as Kapton wire of reduced diameter. The Pyle 83723 family provides connectors in environmental, firewall and hermetic classes that exceed the most stringent specification requirements.

Features & Benefits:

High-Temperature Style Connectors

- High-temperature connector materials and contacts provide operation to 392 °F (200 °C) and Firewall capability to 500 °F (260 °C)

- Improved metal-to-metal bottoming design

- Unique sealing grommet accepts a wide range of wire diameters

- Improved 360° accessory orientation teeth provide greater performance under vibration

- Patented non-decoupling device (torque differential)

- Improved shell-to-shell conductivity with optional RFI grounding fingers

- Styles available that meet several European specifications, General Electric and Rolls Royce specifications

- Special Shell Geometry Styles available

- Bayonet or Threaded Coupling; Hermetic options also available

| Military | M83723/82 with Sockets, Classes G, K |

| Military | M83723/83 with Pins, Classes G, K |

| Commercial | BT( )-17 With ‘O’ ring seal, Classes G, K |

| Commercial - for General Electric | BJ-17 With Static Dynamic Seal, Stainless Steel, but not available in Firewall |

| BJ8-17 Same as BJ-17 except with Scoop-proof recessed pins |

|

| BN-17 Same as BJ-17 except for Electro-deposited Nickel Base |

|

| BN8-17 Same as BN-17 except with Scoop-proof recessed pins |

|

| BNK-17 Same as BN except for Stainless Steel Firewall |

|

| Special with Boeing Designation |

BACC63CN** |

| Commercial - Special per Boeing Co. Spec. | BSK-17 Stainless Steel Firewall with ‘O’ ring seal, qualified to Boeing, Y126 Variation - with Boeing approved contacts |

| Commercial - ASD Designation |

EN2997 ( )0 |

| Commercial - Meets Several European Standards | BT( )-17 With ‘O’ ring seal, Classes G, K Variations for Euro market specifications |

|

BJ( )-17 |

|

| Commercial - Meets Society of British Aerospace Co./Rolls Royce Standards | ESC10 ( )0 260°C Firewall (Classes KE, SE, YE), 360° accessory teeth per MS3155 |

| ESC11 ( )0 260°C Firewall (Classes KE, SE, YE), Scoop-proof recessed pins, 360° accessory teeth per MS3155 |

|

| Note: ESC10 & ESC11 also available in Hermetic square flange receptacles | |

| ESC11 with Scoop-Proof (Recessed pins) | HTK-17 Standard ESC11, Class K Firewall, Scoop-proof, Variations for Euro market specifications |

| HNK-17 Nickel finish, Class K Firewall Mating recept. has ‘O’ ring seal, Scoop-proof, Variations for Euro market specs |

|

| HSK-17 Same as HTK, except this is a special designator for Boeing Co. |

| Military | M83723/84 with Sockets, Classes G, K |

| Military | M83723/85 with Pins, Classes G, K |

| Commercial | BT( )-19 With ‘O’ ring seal, Classes G, K |

| Commercial Special for General Electric: | BJ-19 With Static Dynamic Seal, Stainless Steel, but not available in Firewall |

| BJ8-19 Same as BJ-19 except with Scoop-proof recessed pins |

|

| BN-19 Same as BJ-19 except for Electro-deposited Nickel Base |

|

| BN8-19 Same as BN-19 except with Scoop-proof recessed pins |

|

| BNK-17 Same as BN except for Stainless Steel Firewall |

|

| Commercial - ASD Designation |

EN2997 ( )7 |

| Commercial - Meets Several European Standards | BT( )-19 With ‘O’ ring seal, Classes G, K Variations for Euro market specifications |

|

BJ( )-19 |

|

| Commercial - Meets Society of British Aerospace Co./Rolls Royce Standards | ESC10 & ESC 11 Jam nut receptacles are available in Hermetic only |

| Military | M83723/86 with Sockets, Classes G, K |

| Military | M83723/87 with Pins, Classes G, K |

| Commercial | BT( )-11 With ‘O’ ring seal, Classes G, K |

| Commercial - for General Electric | BJ-11 With Static Dynamic Seal, Stainless Steel, but not available in Firewall |

| BJ8-11 Same as BJ-11 except with Scoop-proof recessed pins |

|

| BN-11 Same as BJ-11 except for Electro-deposited Nickel Base |

|

| BN8-11 Same as BN-11 except with Scoop-proof recessed pins |

|

| BNK-11 Same as BN except for Stainless Steel Firewall |

|

|

No Boeing straight plug designations. No ASD or other European/ESC10 or ESC11 straight plug designations. |

|

| Military |

M83723/95 with Sockets, Classes G, K |

| M83723/96 with Pins, Classes G, K |

|

| M83723/97 with EMI Grounding spring, with Pins |

|

| M83723/97 with EMI Grounding spring, with Sockets |

|

| Commercial | BT( ) 12 Mating receptacle has ‘O’ ring seal, Classes G, K |

| Commercial - for General Electric | BJ-12 With Static Dynamic Seal, Stainless Steel, but not available in Firewall |

| BJ8-12 Same as BJ-12 except with Scoop-proof recessed pins |

|

| BN-12 Same as BJ-12 except for Electro-deposited Nickel Base |

|

| BN8-12 Same as BN-12 except with Scoop-proof recessed pins |

|

| BNK-12 Same as BN except for Stainless Steel Firewall |

|

| Special with Boeing Designation |

BACC63CM** |

| Commercial - Special per Boeing Co. Spec. | BSK-12 Stainless Steel Firewall qual. to Boeing, Y126 Variation - with Boeing approved contacts |

| Commercial - ASD Designation |

EN2997 ( )6 |

| Commercial - Meets Several European Standards | BT( )-12 Mating receptacle has ‘O’ ring seal, Classes G, K Variations for Euro market specifications |

|

BJ( )-12 |

|

| Commercial - Meets Society of British Aerospace Co./Rolls Royce Standards | ESC10 ( )6 260°C Firewall (Classes KE, SE), 360° accessory teeth per MS3155 |

| ESC11 ( )6 260°C Firewall (Classes KE, SE), Scoop-proof, 360° accessory teeth per MS3155 |

|

| ESC11 with Scoop-Proof (Recessed pins) | HTK-12 Standard ESC11, Class K Firewall, Scoop-proof, Variations for Euro market specifications |

| HNK-12 Nickel finish, Class K Firewall Mating recept. has ‘Static Dynamic seal, Scoop-proof, Variations for Euro market specs |

|

| HSK-12 Same as HTK, except this is a special designator for Boeing Co. |

**BACC63CM supersedes BACC63BR.

No Bayonet style Non-Decoupling plug available.

| Military | M83723/71 with Sockets, Classes G, K |

| Military | M83723/72 with Pins, Classes G, K |

| Commercial | BY( )-17 With ‘O’ ring seal, Classes G, K |

| Military | M83723/73 with Sockets, Classes G, K |

| Military | M83723/74 with Pins, Classes G, K |

| Commercial | BY( )-19 With ‘O’ ring seal, Classes G, K |

| Military | M83723/75 with Sockets, Classes G, K |

| Military | M83723/76 with Pins, Classes G, K |

| Commercial | BY( )-10 With ‘O’ ring seal, Classes G, K |

| Military | M83723/88Y Stainless Steel, Class Y, Solderwell contacts |

| Military | M83723/88P Stainless Steel, Class P, Eyelet contacts |

| Commercial | BTY( )-17 Stainless Steel, ‘O’ ring Seal, Solderwell or Eyelet contacts, 200°C or 260°C |

| BFY-17 Stainless Steel, Static Dynamic Seal, Solderwell or Eyelet contacts, 200°C or 260°C |

|

| BNY-17 Stainless Steel, Static Dynamic Seal, Electro-deposited Nickel, Solderwell or Eyelet contacts, 200°C or 260°C |

|

| Commercial - ASD Designation |

EN2997Y0 / YE0 |

| Commercial - Meets Society of British Aerospace Co./ Rolls Royce Standards |

ESC10YE2 260°C Firewall, Stainless Steel, Class YE, Solderwell contacts |

| ESC11YE2 260°C Firewall, Stainless Steel, Class YE, Solderwell contacts, scoop-proof Recessed pins PCB Tails available upon request |

| Military | M83723/89Y Stainless Steel, Class Y, Solderwell contacts |

| Military | M83723/89P Stainless Steel, Class P, Eyelet contacts |

| Commercial | BTY( )-19 Stainless Steel, ‘O’ ring Seal, Solderwell or Eyelet contacts, 200°C or 260°C |

| BFY-19 Stainless Steel, Static Dynamic Seal, Solderwell or Eyelet contacts, 200°C or 260°C |

|

| BNY-19 Stainless Steel, Static Dynamic Seal, Electro-deposited Nickel, Solderwell or Eyelet contacts, 200°C or 260°C |

|

| Commercial - ASD Designation |

EN2997Y7 / YE7 |

| Commercial - Meets Society of British Aerospace Co./ Rolls Royce Standards |

ESC10YE3 260°C Firewall, Stainless Steel, Class YE, Solderwell contacts |

| ESC11YE3 260°C Firewall, Stainless Steel, Class YE, Solderwell contacts, scoop-proof Recessed pins PCB Tails available upon request |

Commercial BTY, BFY and BNY meet European specifications and General Electric spec. GEM50TF3564, Classes A & B.

Shell sizes 20, 24 and 28, consult Amphenol Aerospace for availability.

Hermetic style receptacles are not included in Boeing designations.

| Military | M83723/90Y Stainless Steel, Class Y, Solderwell contacts |

| Military | M83723/90P Stainless Steel, Class P, Eyelet contacts |

| Commercial | BTY( )-14 Stainless Steel, ‘O’ ring Seal, Solderwell or Eyelet contacts, 200°C or 260°C |

| BFY-14 Stainless Steel, Static Dynamic Seal, Solderwell or Eyelet contacts, 200°C or 260°C |

|

| BNY-14 Stainless Steel, Static Dynamic Seal, Electro-deposited Nickel, Solderwell or Eyelet contacts, 200°C or 260°C |

|

| Commercial - ASD Designation |

EN2997Y1 / YE1 |

| Commercial - Meets Society of British Aerospace Co./ Rolls Royce Standards |

ESC10YE1 260°C Firewall, Stainless Steel, Class YE, Solderwell contacts |

| ESC11YE1 260°C Firewall, Stainless Steel, Class YE, Solderwell contacts, scoop-proof Recessed pins PCB Tails available upon request |

Commercial BTY, BFY and BNY meet European specifications and General Electric spec. GEM50TF3564, Classes A & B.

Shell sizes 20, 24 and 28, consult Amphenol Aerospace for availability.

Hermetic style receptacles are not included in Boeing designations.

%20Receptacle,%20Threaded%20Coupling.png)

These connectors meet the performance requirements of the following manufacturer's specifications:

• Boeing BACC63CM/CN* Firewall

• European: ASD† EN2997

• General Electric: M50TF3564

• Rolls Royce/SBAC: ESC10 and ESC11

| MIL-DTL-83723, Series III Connector Performance Characteristics | |

| Operating Temperature Data | Std: –85°F (–65°C) to 392°F (200°C) Class K types meet fireproof test per MIL-DTL-83723 2000°F (1093°C) High-Temperature Series: Operates at 500°F (260°C) |

| Altitude | Sea Level to 110,000 feet |

| Voltage Breakdown Rating |

Service Rating I |

| Contact Rating | Size 20 contacts : 7.5 amperes max. Size 16 contacts : 13.0 amperes max. Size 12 contacts : 23 amperes max. |

| Contact Retention Strength | Exceeds MIL-DTL-83723 requirements |

| Connector Durability | 500 cycles per MIL-DTL-83723 for threaded coupling; 500 cycles per General Electric M50TF2321 for non-decoupling styles |

| Humidity | To 98% relative humidity, including condensation |

| Exposure | Freezing rain |

| Non-Decoupling | Exceeds requirements of MIL-DTL-83723/95 and 96 |

| Vibration | Meets MIL-DTL-83723 of 41.7G’s for 16 hours.; Boeing BACC63CM/CN for 36 hours General Electric vibration spec. M50TF2321 and M50TF2238 for 36 hours, which includes: Temp. Extremes G Level Time Length Room Temp.............. 60 G’s .......... 12 hrs. (4 hrs. each axis) –65°F ±5°F ............... 60 G’s ........... 12 hrs. (4 hrs. each axis) 350°F ±5°F ............... 60 G’s ............12 hrs. (4 hrs. each axis) |

| Hermetic Connector Performance Characteristics | |

| Thermal Shock | No damage detrimental to the operation of the connector occurs when subjected to 10 cycles of thermal shock from 0°C to 90°C and back to 0°C. |

| Physical Shock (Mated) | 300 G’s |

| Moisture Resistance (Mated) | 500 Megohms |

| Insulation Resistance, High Temp. (Mated) | 500 Megohms |

| Corrosion (Unmated) | Complies with MIL-DTL-83723 Req. |

| Temperature Life | Fully functional for 1000 hours at 200°C (392°F) ambient. Internal temperature 238°C (460°F). |

| Air Leakage (Unmated) | Less than .01 micron per cubic feet per hour on the application of 15 PDS pressure differential across the connector |

| Altitude Immersion (Mated) | After 3 cycles immersed in saltwater with pressure reduced to 1 in. Hg (75,000 ft. altitude) for 30 minutes and returned to atmospheric pressure. While connectors submerged insulation resistance should remain 1000 megohms minimum and support 1500 volts RMS applied without flash-over or breakdown. |

| High Potential Voltage Altitude (Unmated) |

When tested in accordance with MIL-STD-202, Method 301, no flash-over or breakdown under simulated altitude conditions as shown: Altitude/Service Rating I |

Military and Commercial Service Classes

| G | Stainless steel, 200°C |

| K | Stainless steel, 200°C firewall capability |

| S | Stainless steel, 200°C firewall capability, Grounding Spring |

| P | Stainless steel, 200°C, hermetic with eyelet contacts |

| Y | Stainless steel, 200°C, hermetic with solderwell contacts |

| KE | Stainless steel, high temp. (260°C) firewall capability |

| SE | Stainless steel, high temp. (260°C) firewall capability, grounding spring |

| YE | Stainless steel, high temp. (260°C) firewall capability, hermetic with solderwell contacts |

Note: For Classes A, R and W (aluminum shell types) - Amphenol supplies these in their Matrix 83723 family

%20or%20.png)

%20Receptacle,%20Bayonet%20Coupling.png)

%20Receptacle,%20Threaded%20Coupling.png)

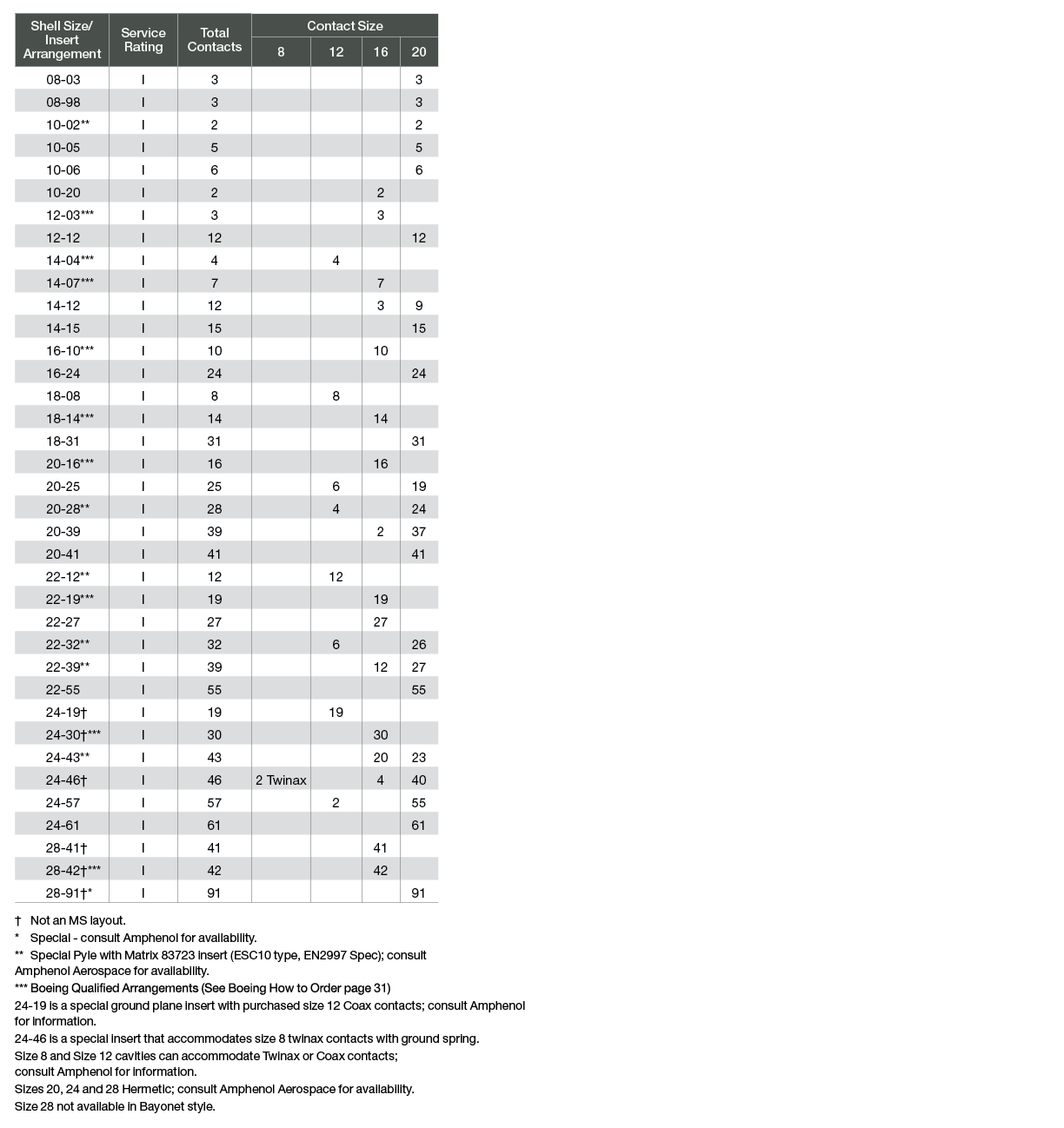

Alternate Keying Positions (Rotation of Key/Keyway of Shell)

To avoid cross-plugging problems in applications requiring the use of more than one connector of the same size and arrangement, alternate keying positions are available as indicated in the chart below. The diagram shows the engaging view of a receptacle shell with keyways. The insert is rotated counter-clockwise relative to the center-line. Plug shells would be the opposite of this diagram.

In the “Normal insert position” (position N), the insert center line coincides with the center-line of the master key/keyway of the shell. In the “alternate keying positions” (positions 6, 7, 8, 9 and Y), the minor keys/keyways are positioned with reference to master key/keyway as indicated in the keying position table.