Accessories for 2M Micro-Miniature Connectors

Contact:

Description:

A complete line of accessories for all 2M connectors including backshells, protection caps, strain reliefs, micro-band adapters, as well as the 2M Python - the low-profile EMI/RFI plug and backshell combination.

Features & Benefits:

Includes:

- Backshells

- Protection Caps

- Strain Reliefs

- Micro Band Adapters

- Shorting Caps

- Shrink Boots

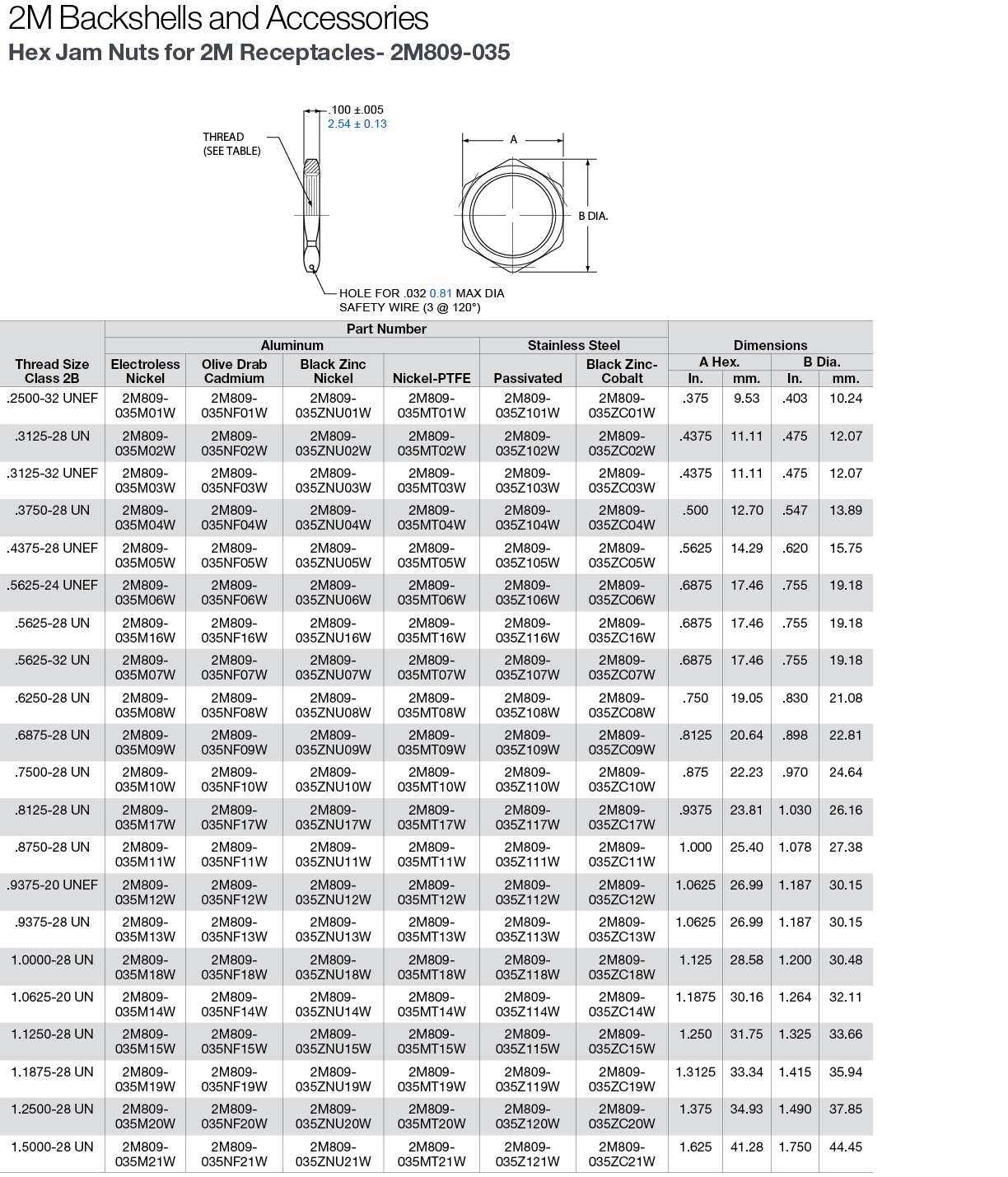

- Hex Jam Nuts

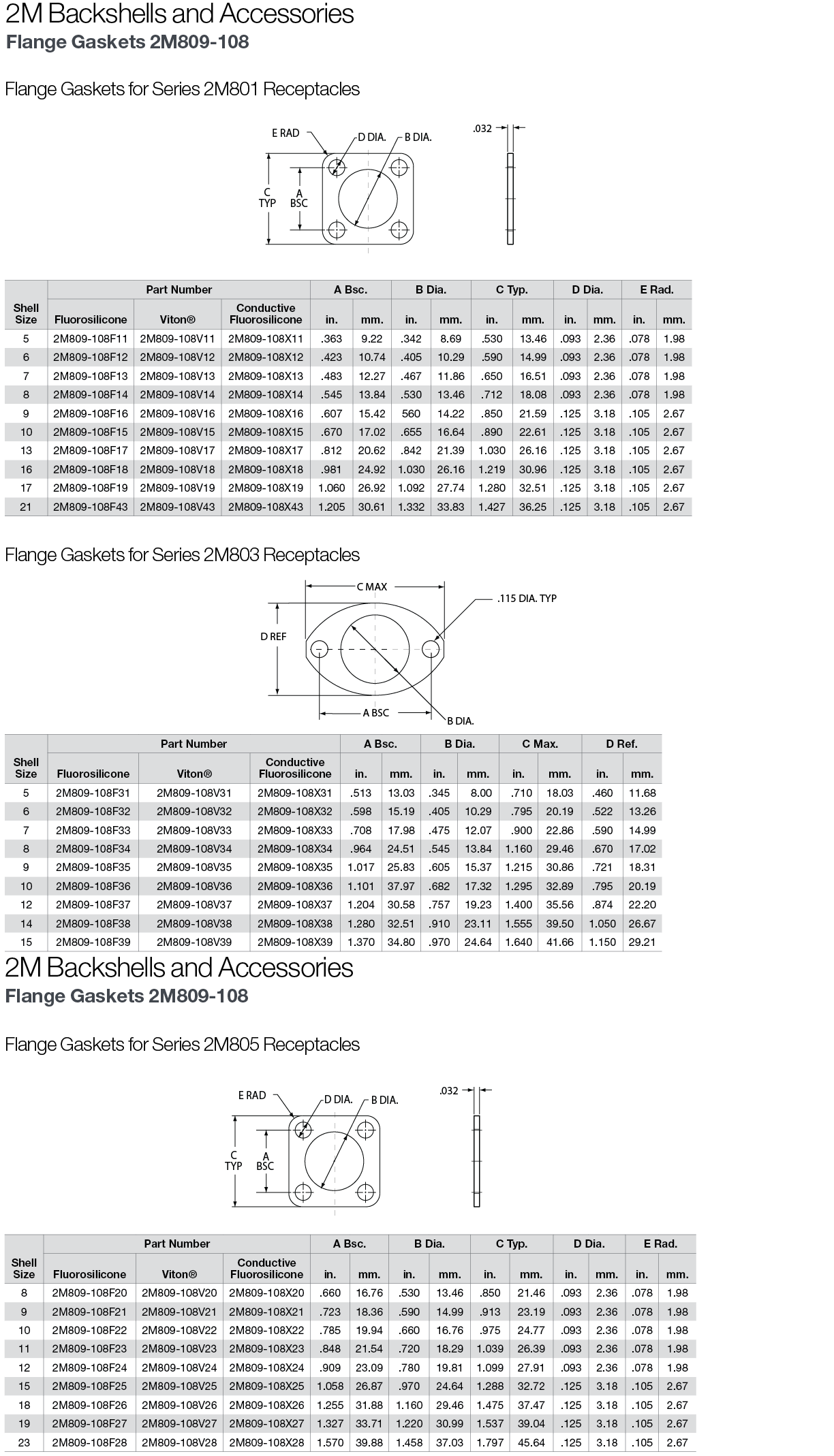

- Flange Gaskets

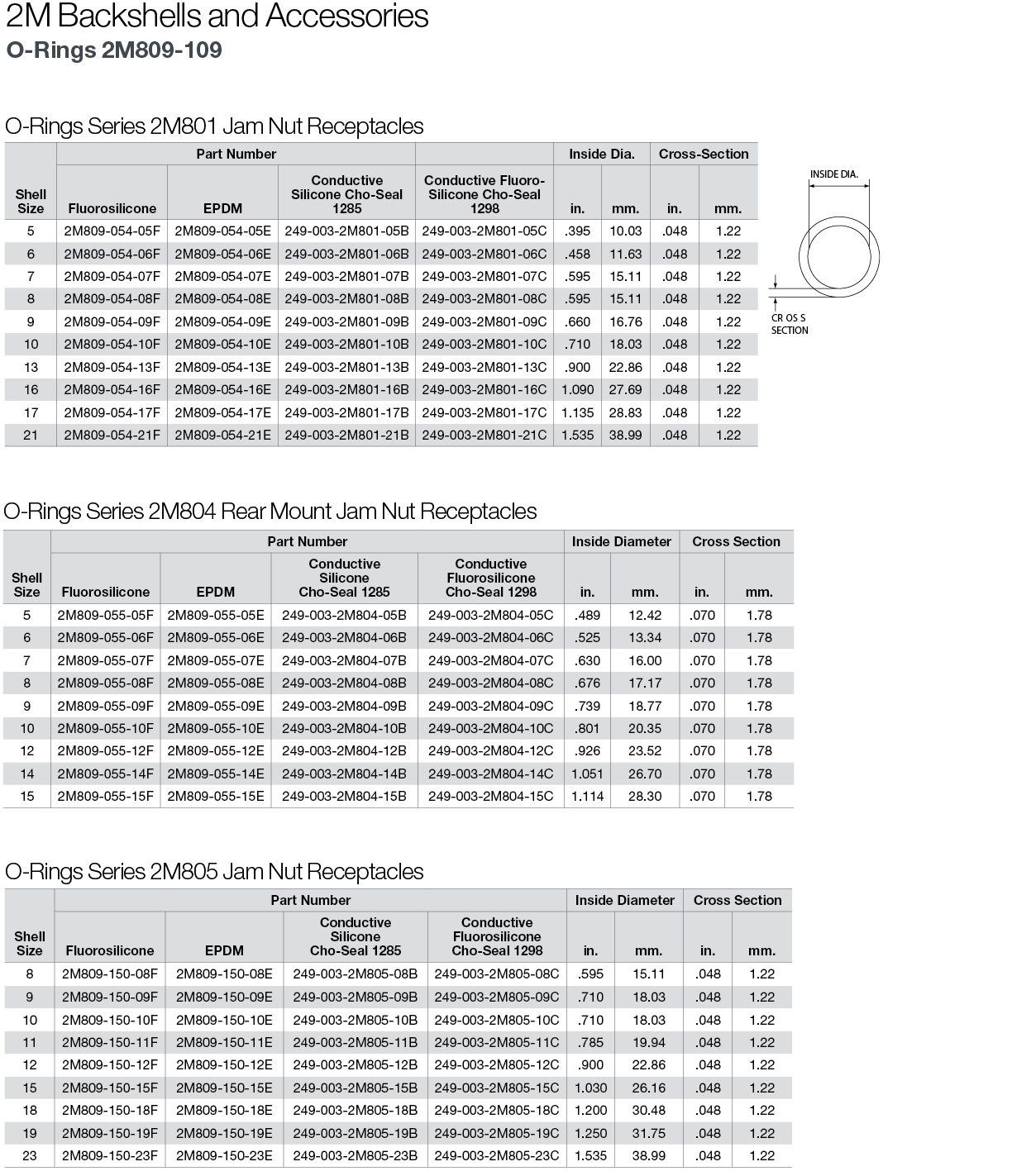

- O-Rings

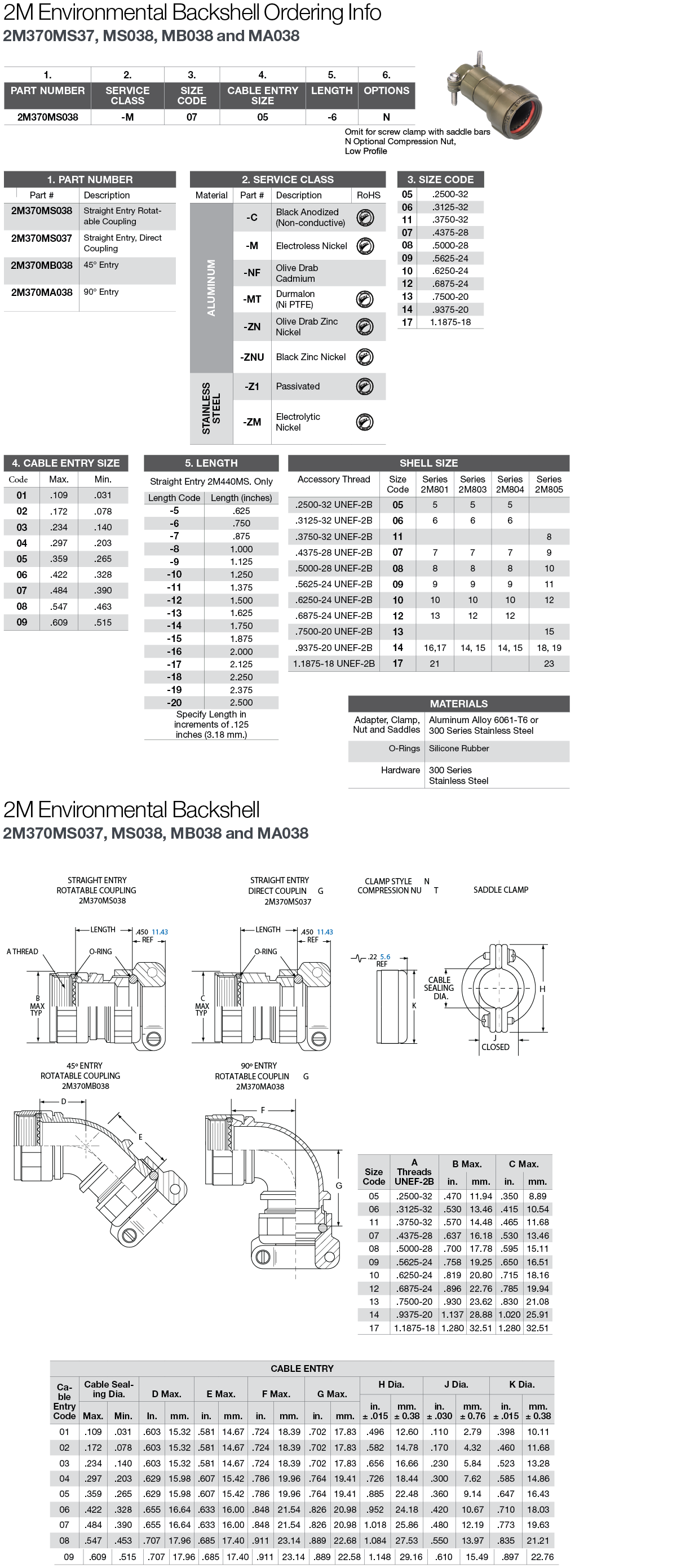

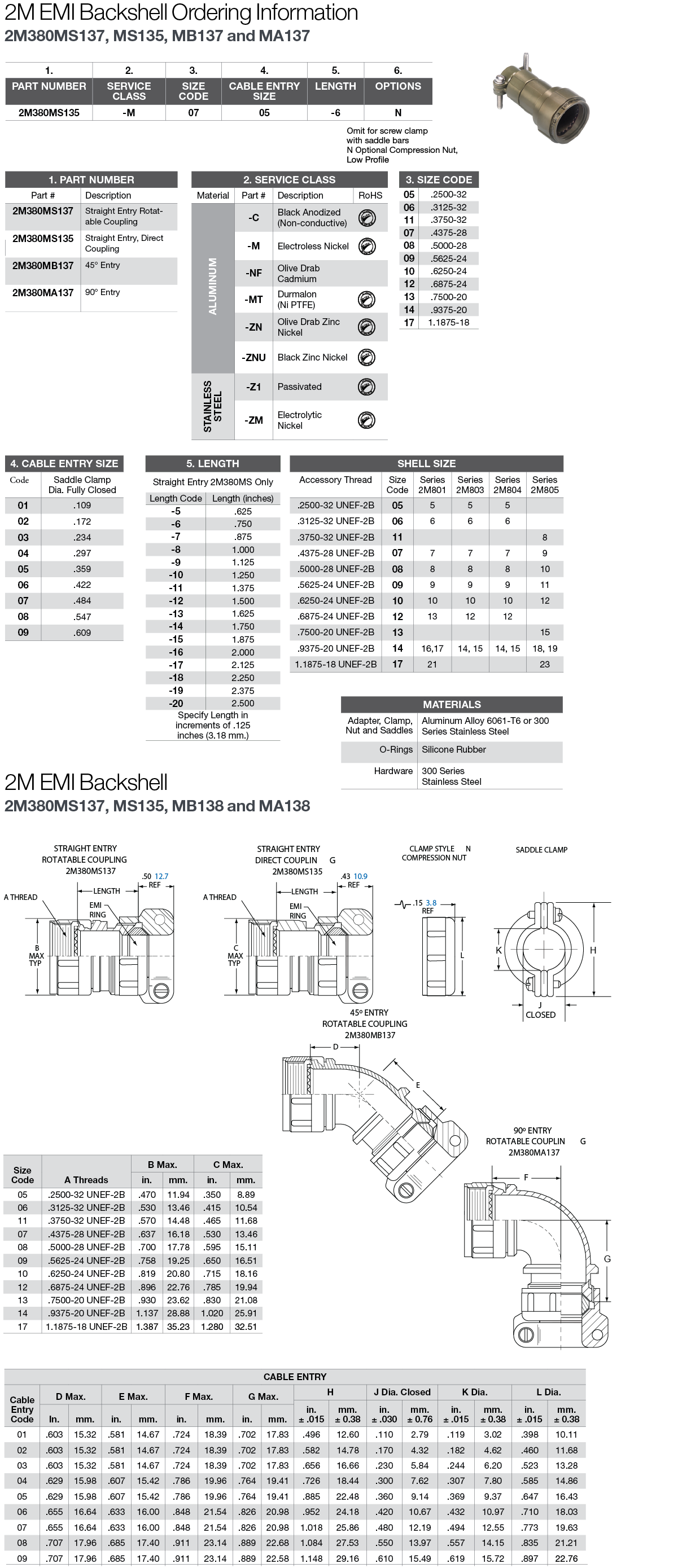

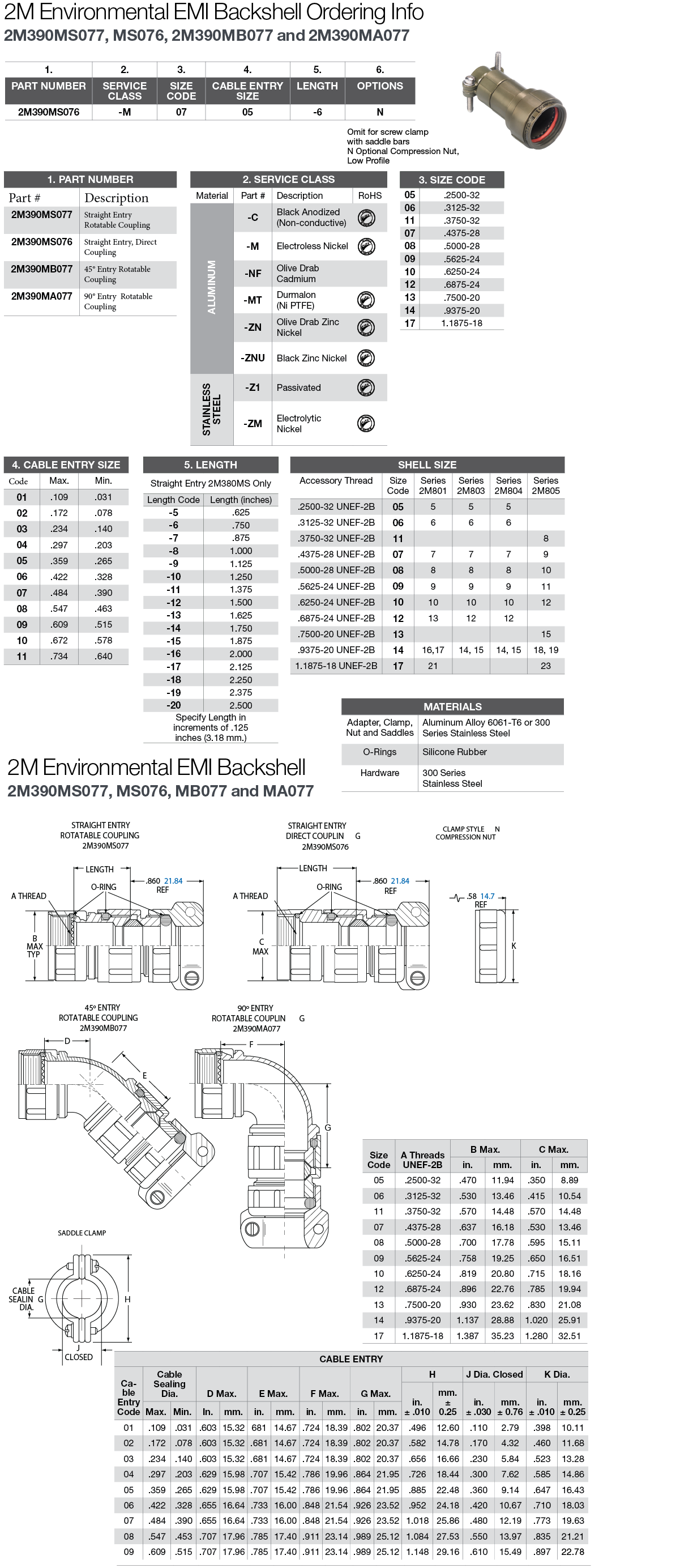

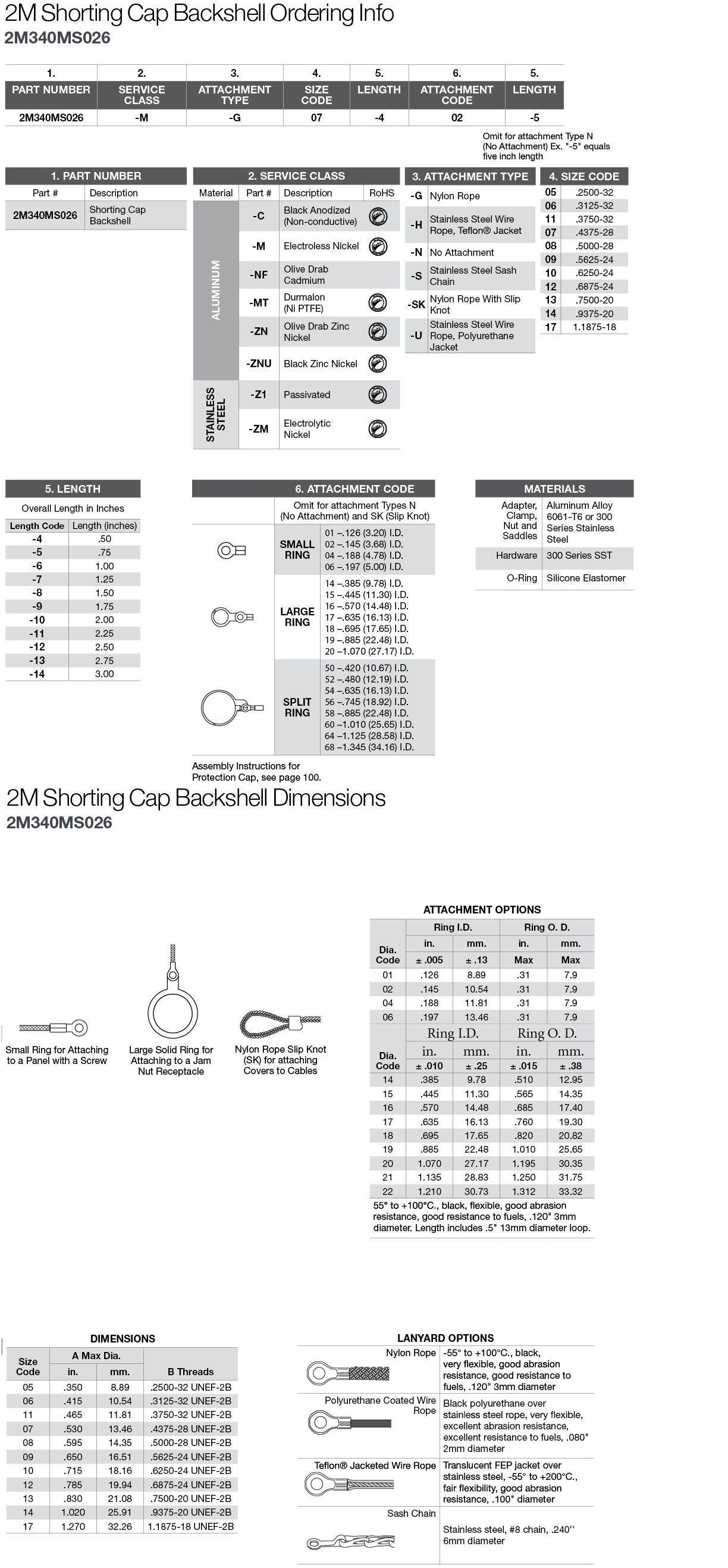

Backshells

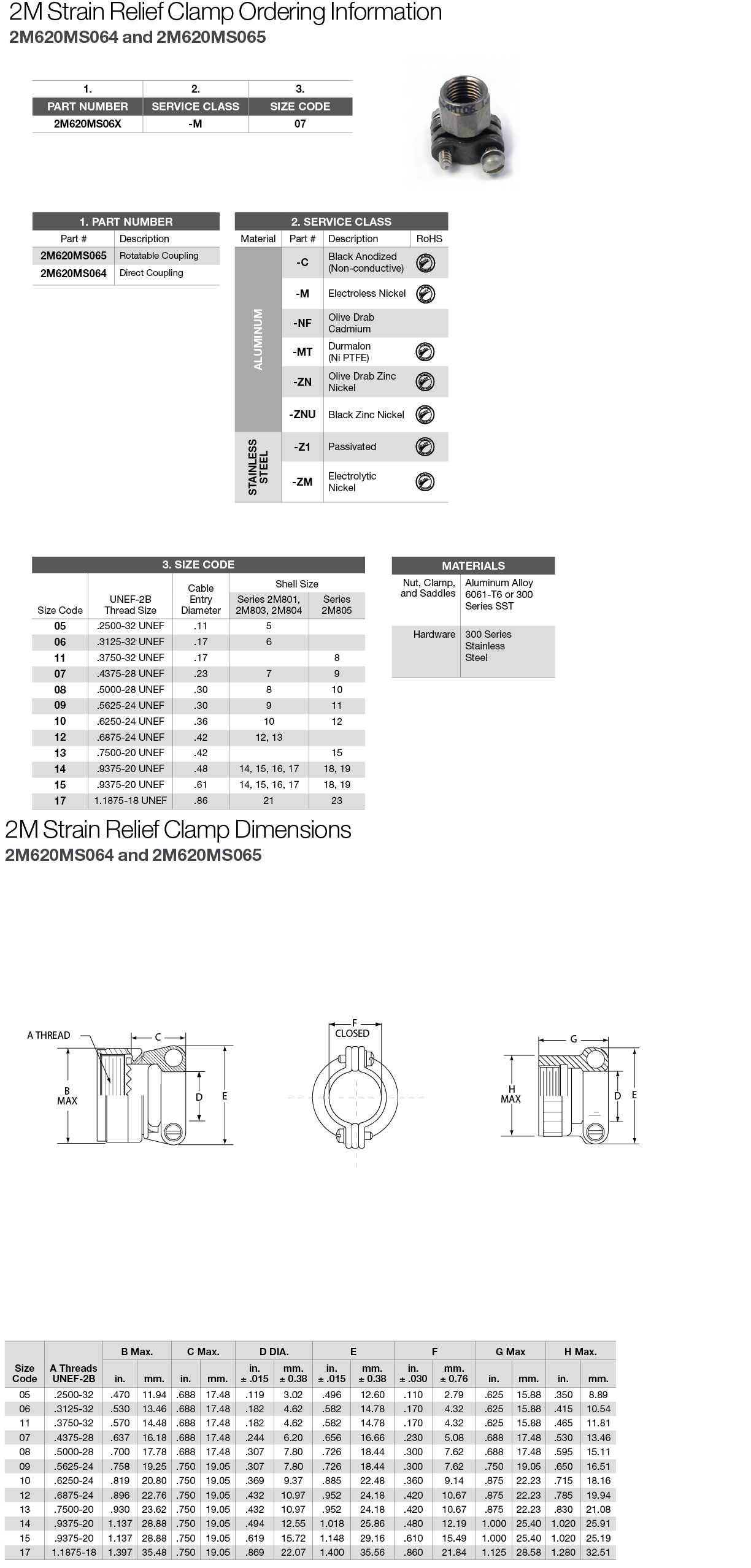

Strain Relief Clamps

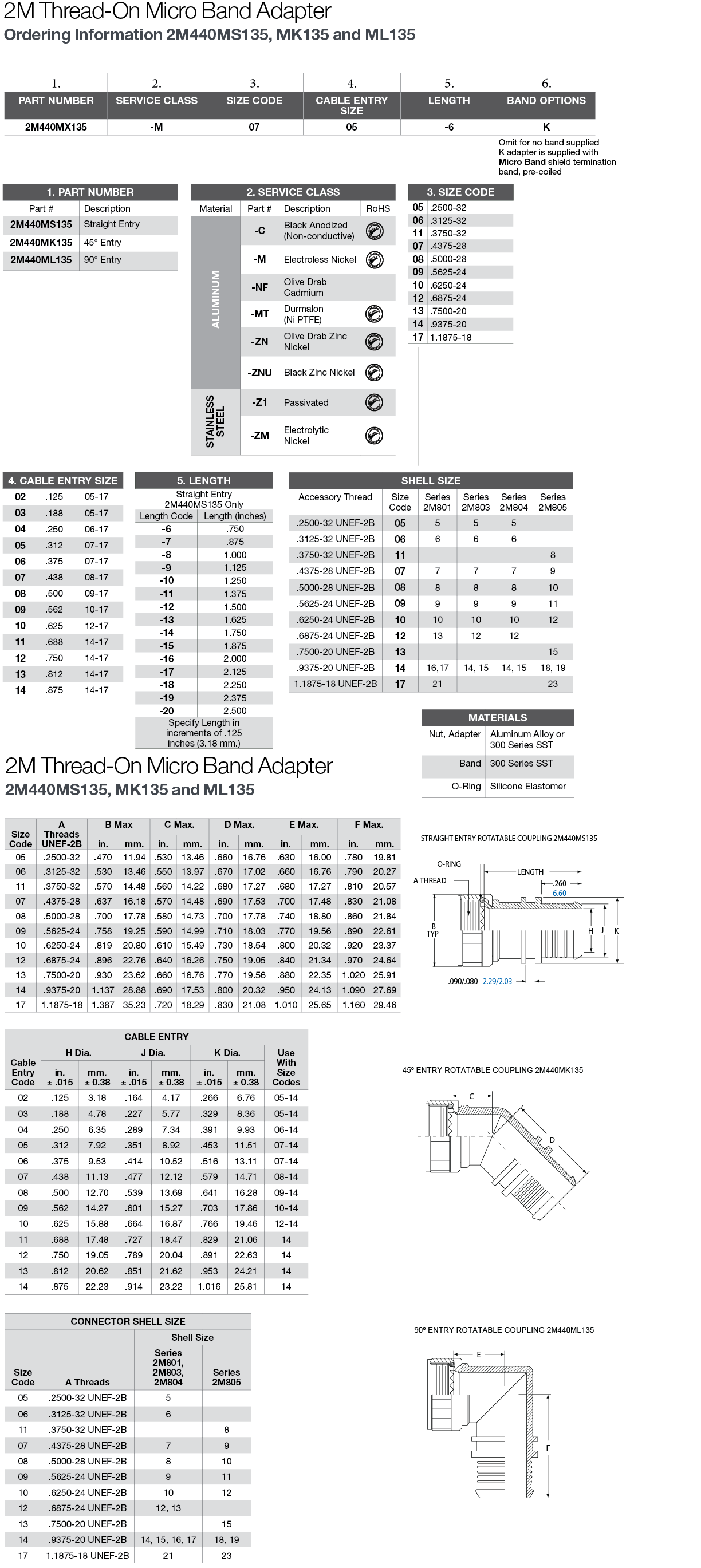

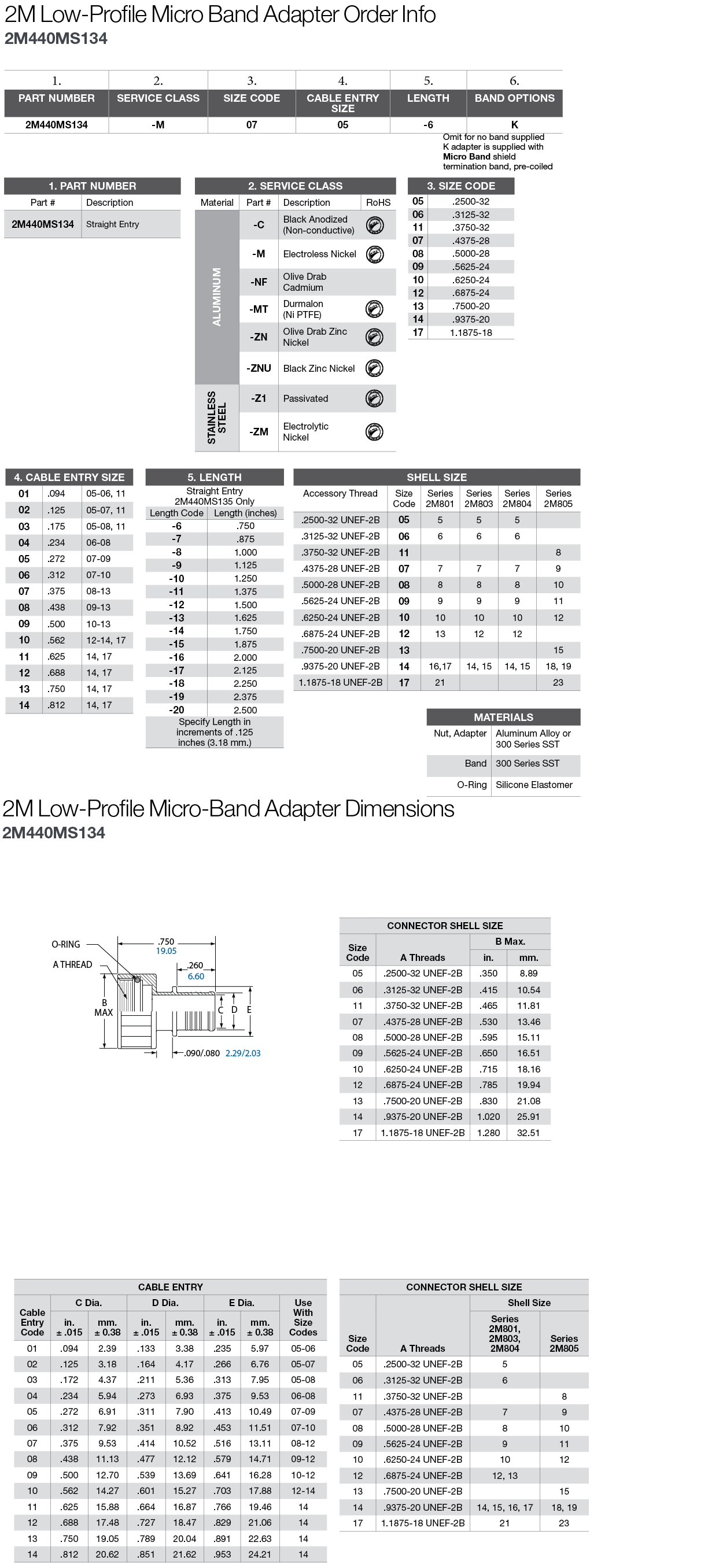

Micro-Band Adapters

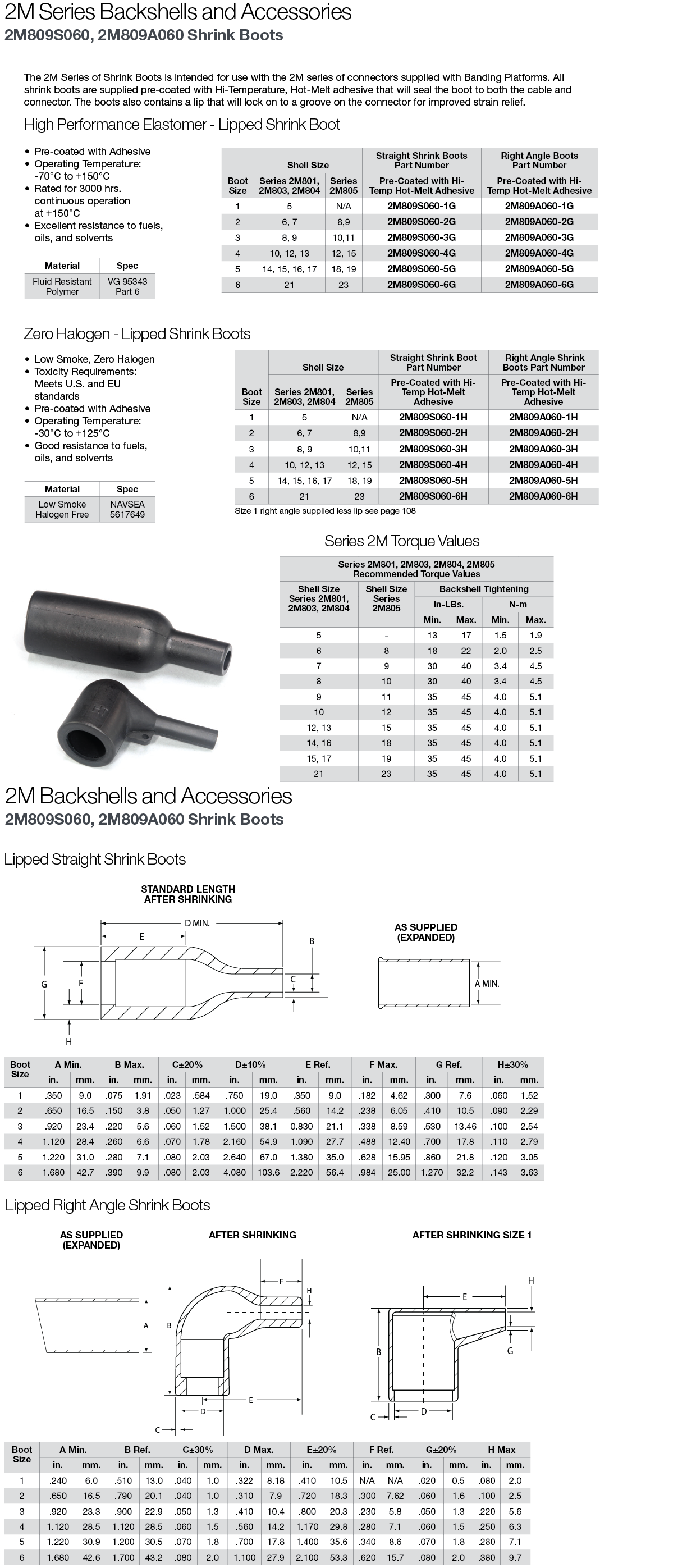

Shrink Boots

Hex Jam Nuts

Flange Gaskets

O-Rings

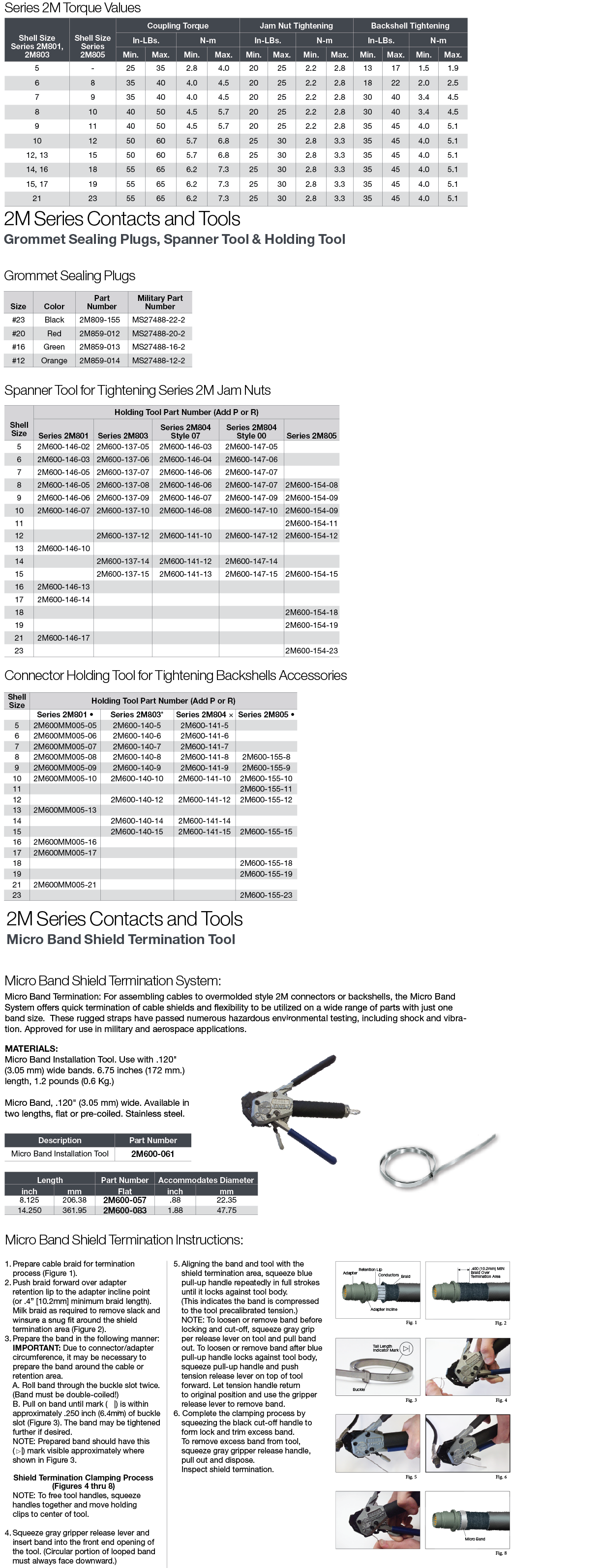

Tool Information

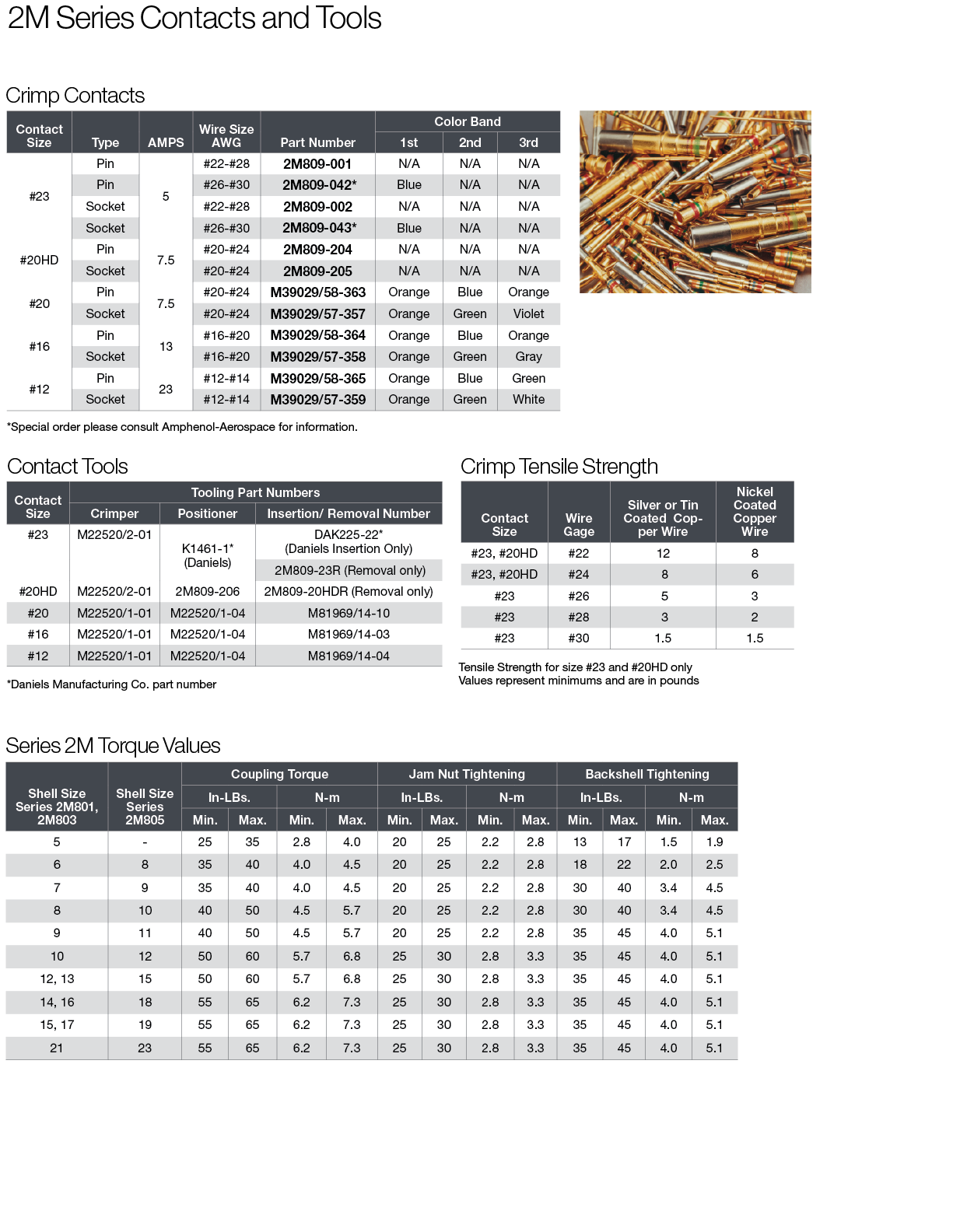

Contacts and Tool Information

Assembly Instructions

Wire Stripping

- Strip wire to required length. When using hot wire stripping, do not wipe melted insulation material on wire strands; with mechanical strippers do not cut or nick strands.

- See Table 1 for proper finished outside wire dimensions.

- Twist strands together to form a firm bundle.

- Insert stripped wire into contact applying slight pressure until wire insulation butts against wire well. Check inspection hole to see that wire strands are visible. If there are strayed wire strands, entire wire end should be re-twisted. When wire is stripped and properly installed into contact, the next step is to crimp the wire inside the contact by using the proper crimping tool.

Crimping

- Insert stripped wire into contact crimp pot. Wire must be visible through inspection hole.

- Using correct crimp tool and locator, cycle the tool once to be sure the indentors are open, insert contact and wire into locator. Squeeze tool handles firmly and completely to insure a proper crimp. The tool will not release unless the crimp indentors in the tool head have been fully actuated.

- Release crimped contact and wire from tool. Be certain the wire is visible through inspection hole in contact.

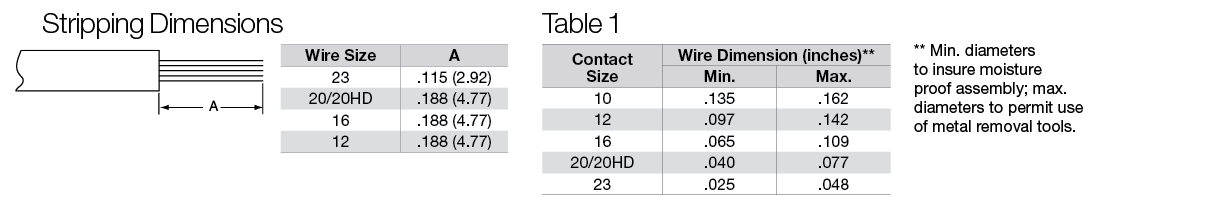

Contact Insertion

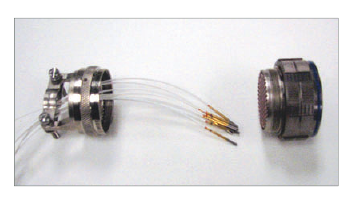

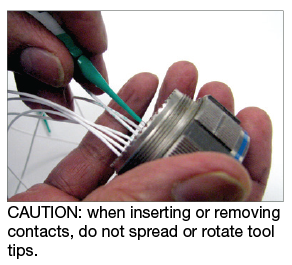

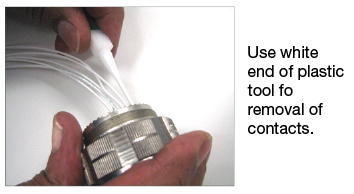

Note: All plastic tools are double-ended. The colored side is the insertion tool and the white side is the removal tool.

- First remove hardware from the plug and receptacle and slide the hardware over wires in proper sequence.

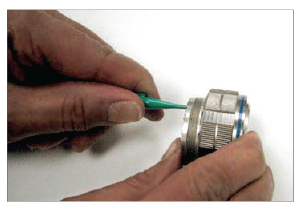

- Use proper plastic or metal insertion tool for the corresponding contact. Slide correct tool (with plastic tool use colored end) over wire insulation and slide forward until tool bottoms against rear contact shoulder.

- Next, align the tool and contact up to the properly-identified cavity at rear of connector plug. Use firm, even pressure; do not use excessive pressure. It is recommended to start at the center cavity. Contact must be aligned with grommet hole and not inserted at an angle. Push forward until contact is felt to snap into position within insert.

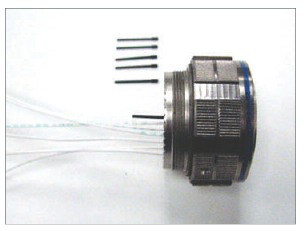

- Remove tool and pull back lightly on wire, making sure contact stays properly seated and isn’t dragged back with the tool. Repeat the operation with the remainder of contacts to be inserted, beginning with the center cavity and working outward in alternating rows.

- After all contacts are inserted, fill any empty cavities with wire sealing plugs.

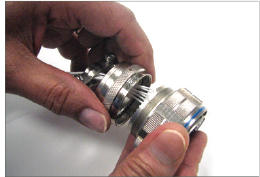

- Reassemble plug or receptacle hardware slide forward and tighten using connector pliers. Connector holding tools are recommended while tightening back accessories. When using strain relief, center wires at bar clamp. Slide clamp grommet into position and tighten clamp bar screws. When tightening screws, pressure should be applied in the same direction that clamp is threaded to rear threads of the connector. When not using clamp grommet, build up wire bundle with vinyl tape so clamp bar will maintain pressure on wires.

Contact Removal

- Remove hardware from plug or receptacle and slide hardware back along wire bundle.

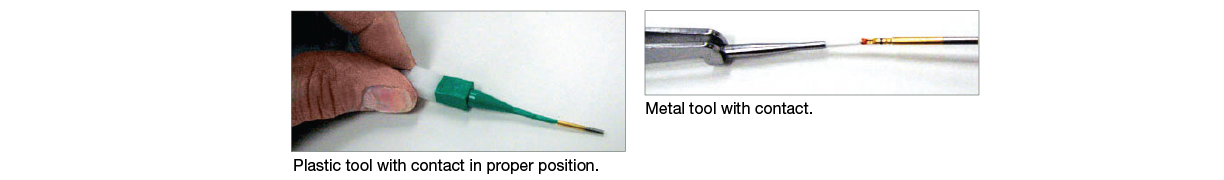

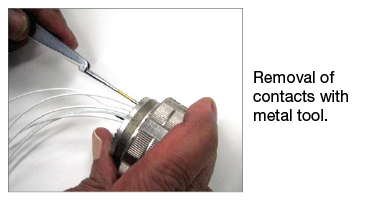

- Use proper plastic or metal removal tool for corresponding contact. Slide correct size tool over wire insulation.

- Insert plastic or metal removal tool into contact cavity until tool tips enter rear grommet and come to a positive stop. Hold tool tip firmly against positive stop on contact shoulder. Grip wire and simultaneously remove tool and contact. (On occasion, it may be necessary to remove tool, rotate 90° and reinsert.)

Amphenol Aerospace 2M Connectors

2:38

2M Hermetic

The small and lightweight 2M Hermetic connector provides an exceptional airtight seal without sacrificing ruggedness and meets or exceeds most MIL-DTL-38999 environmental and performance requirements.

2M Filters

The versatility of standard 2M connectors with EMI protection to meet the demands of your application.

2M805 Tri-Start Threaded Coupling

Tri-Start threaded, ruggedized miniature connectors that meet D38999 requirements at half the size and weight.

2M804 Push-Pull Quick-Disconnect

Ruggedized, push-pull miniature connectors with multiple options for soldier-worn applications.

2M803 1/4 Turn Bayonet Coupling

General purpose, bayonet-coupling miniature connectors for light-duty applications that require frequent disconnect.

2M801 Dual-Start Acme Threads

Dual-Start threaded miniature connectors for applications that require compatibility with existing technologies or cables.