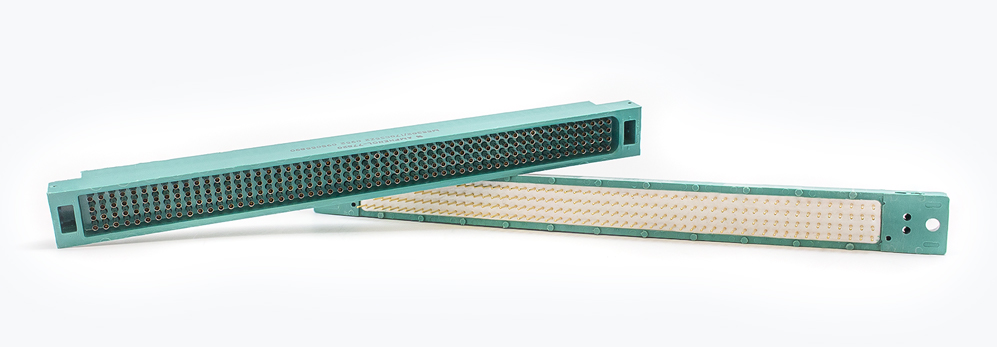

MIL-DTL-55302 Low Mating Force Connectors

Contact:

Description:

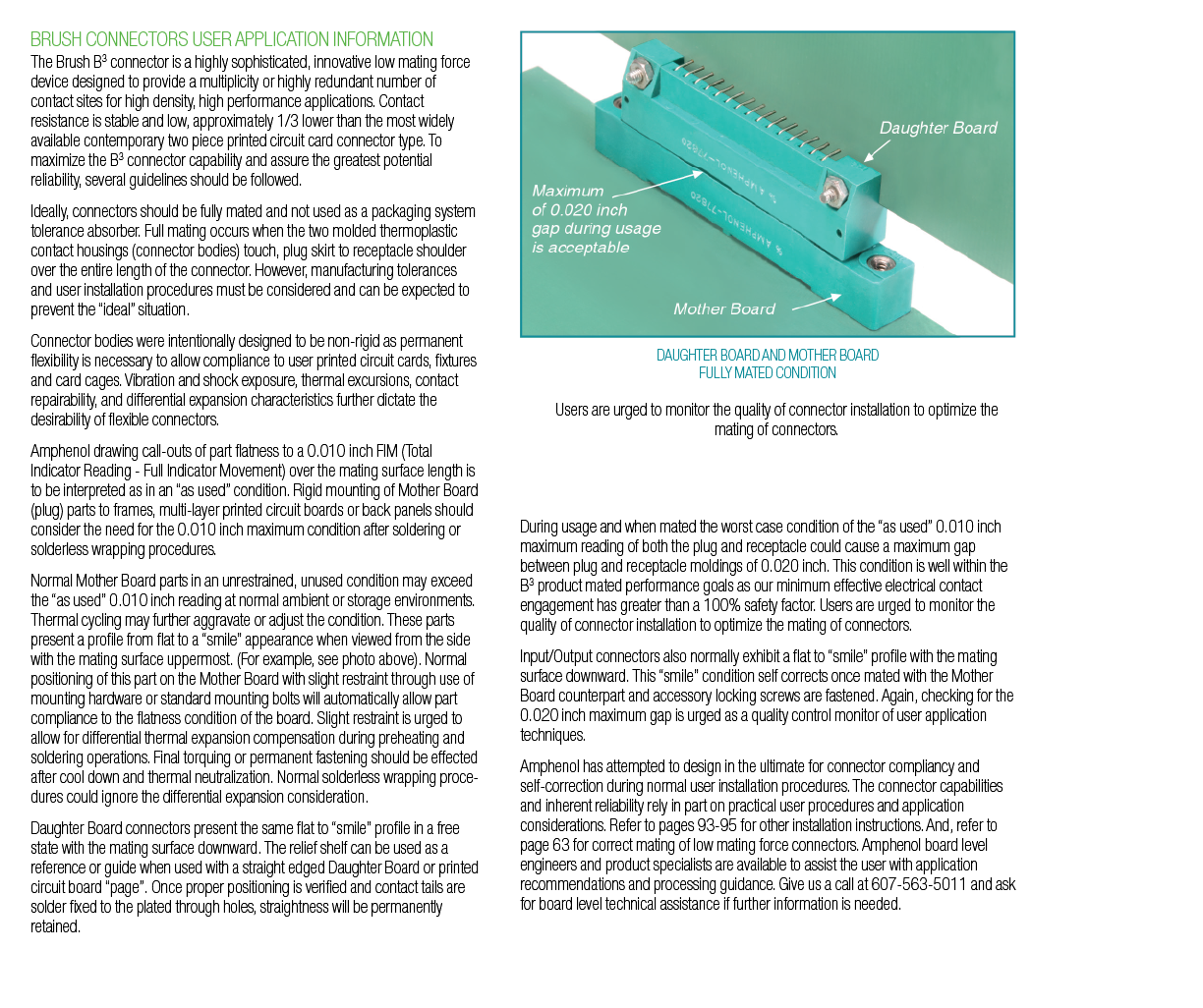

Amphenol’s MIL-DTL-55302 Low Mating Force rectangular connector series is one of the highest performing board connectors in the world, with proven performance on the ground, in the air, and at sea. This series utilizes the B3 brush contact system known for low mating force, stable electrical performance in high vibration, and extended service life.

Features & Benefits:

- 0.100 inch center to center, square grid contact spacing

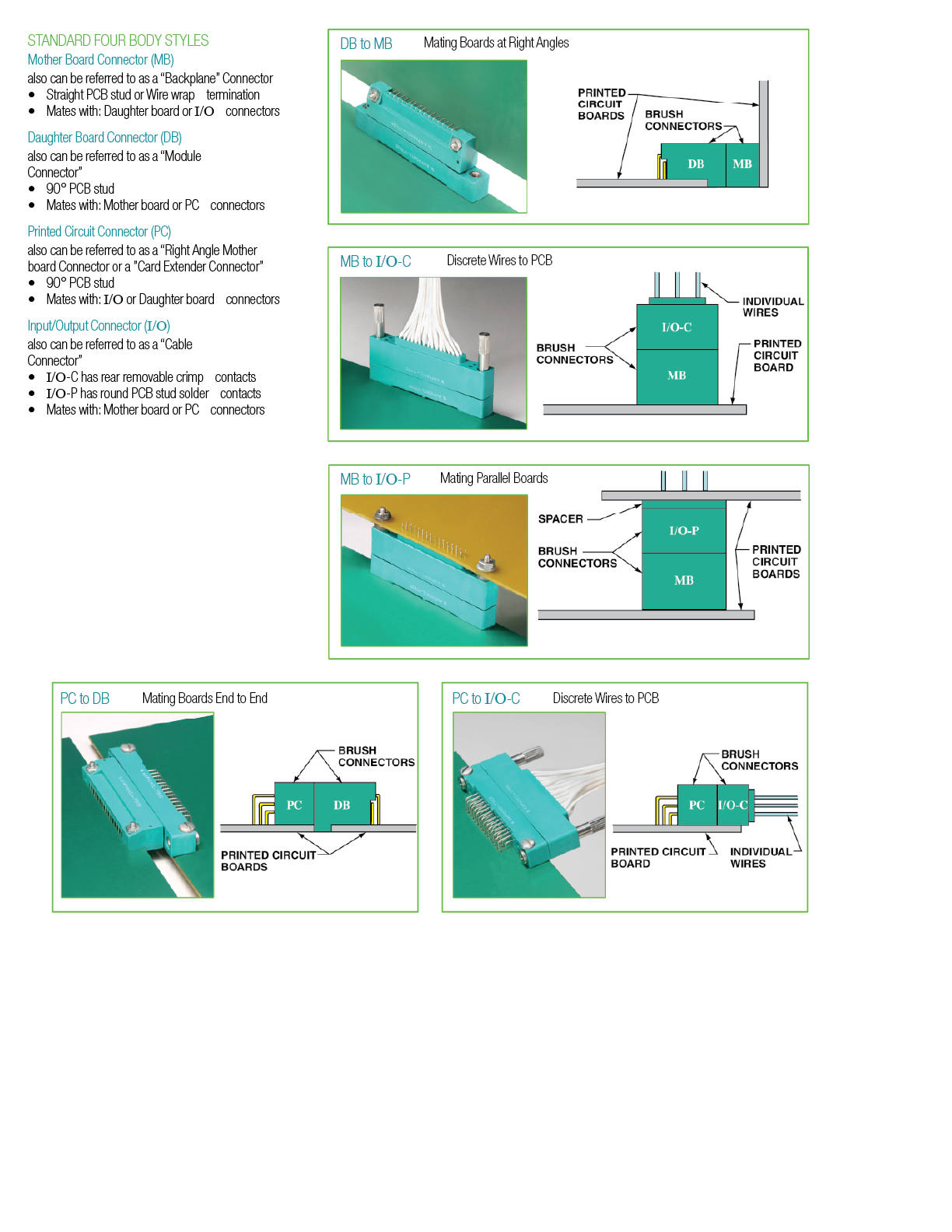

- Application flexibility (parallel boards, perpendicular boards, wire to board, end to end boards, card extenders)

- 2, 3 and 4 row contact arrangements with 10 to 100 contacts per row in one contact per row increments

- Military versions meet MIL-DTL-55302/166 through /172

- Termination versatility; straight & 90° PCB stud, wire wrap & crimp

Performance Specifications

Performance

- voltage rating: SL/1300 70,000 ft./325

- one and one-half ounce average contact engaging/separating forces

- 7 milliohms average contact resistance for row A contacts

- (Resistance will vary depending on the point of measurement and the length of the contact.)

- 3 ampere – PCB contacts; 5 ampere – wire wrap / crimp contacts

- –65°C to +125°C temperature rating

- 5 gigaohms minimum insulation resistance

Materials

- Connector Body – Glass-filled thermoplastic molding material in accordance with MIL-M-24519 type GPT-15F and/or Grade B

- Class 15 of MIL-P-46161 (UL94V-O)

- Polarization Keys – Glass-filled acetal plastic molding material in accordance with MIL-P-46137

- Locking Screw/Mounting Bushing – Corrosion-resistant steel AISI 300 types passivated in accordance with QQ-P-35

Contacts

- Holders – Copper alloy in accordance with Federal Specification QQ-B-626 or SAE J463

- Wire – Berryllium copper in accordance with Federal Specification ASTM B197

- Sleeves – If applicable, stainless steel in accordance with AMS-5514 passivated in accordance with ASTM A967

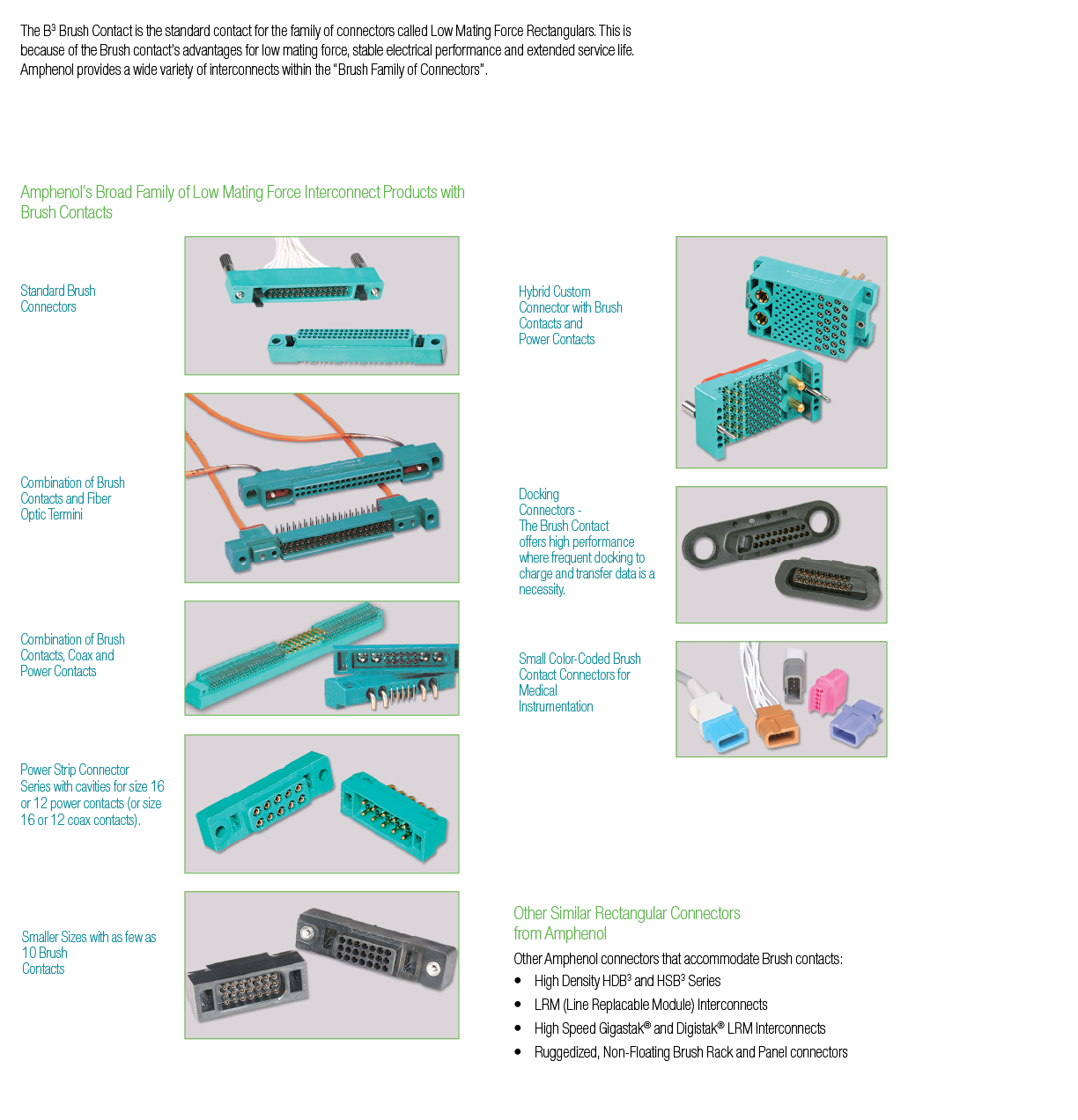

Brush Contact Technology

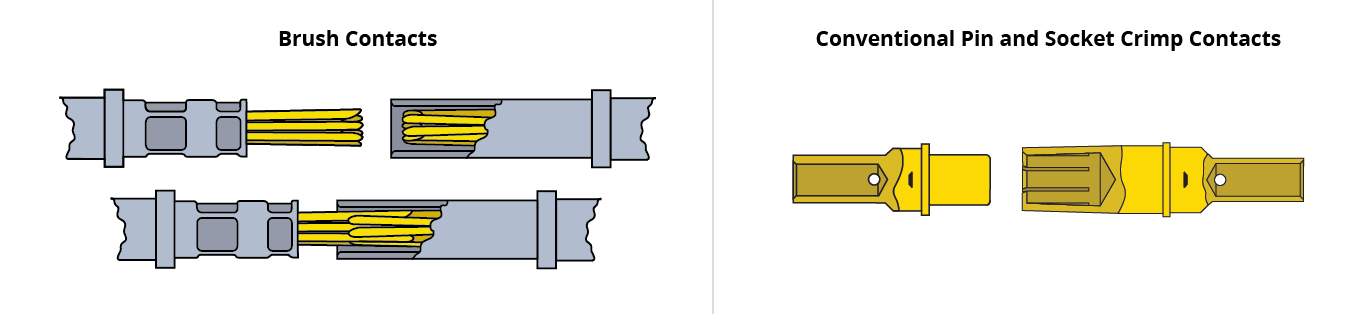

Brush Contacts vs. Conventional Pin and Socket Contacts

Brush Contact Innovation

- Multiple contact interfaces - Strands of high tensile wire are bundled together to form brush-like contacts. By intermeshing two multi-strand wire bundles, an electrical connection is made.

- Provides redundant current paths, 14-70 (points of contact) per mated contact with a gas-tight junction

- Very smooth (low friction) interface

Conventional Pin and Socket

- Machined surface finish on both parts

- Higher friction and wear

- Limited number of contact sites

Connector Options

Mated Pair Options

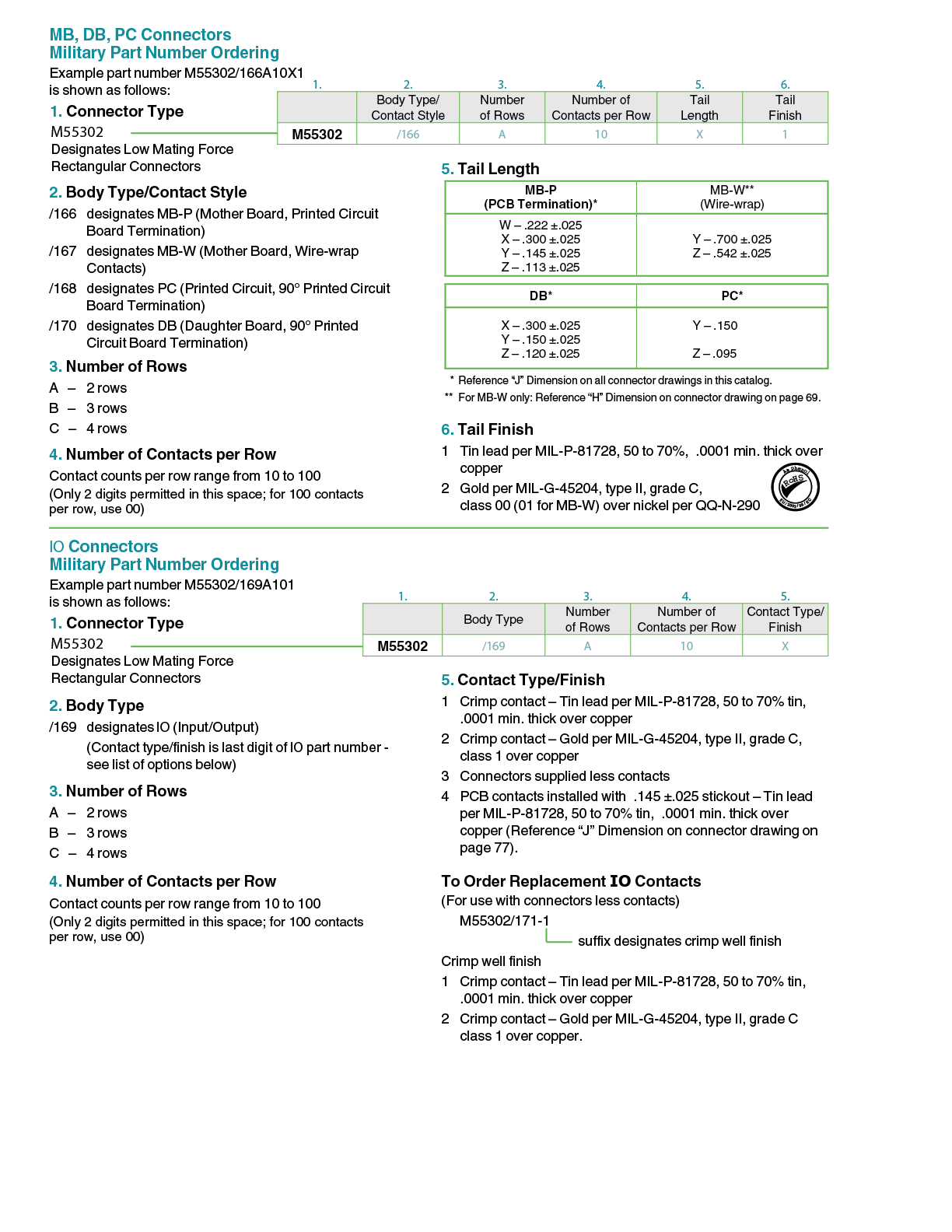

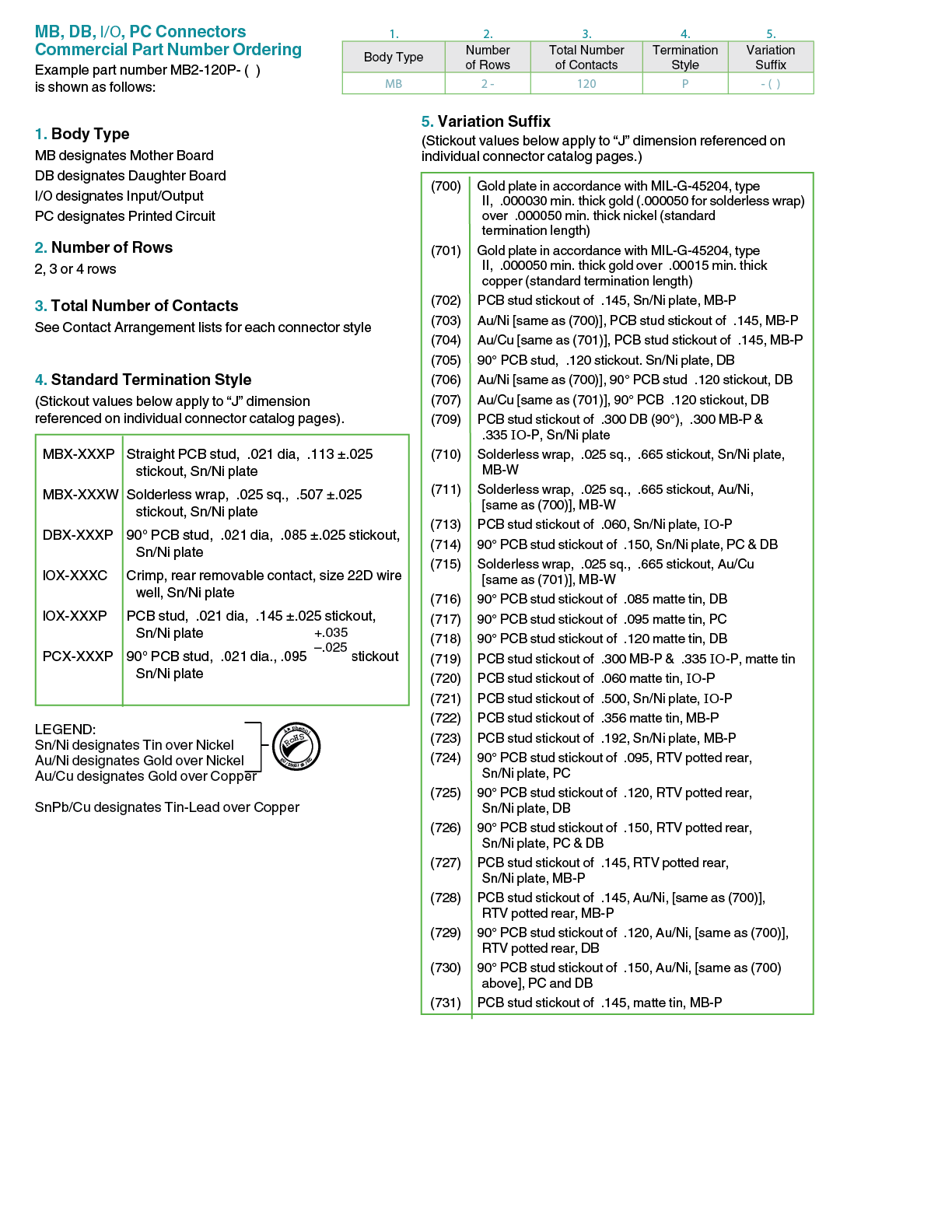

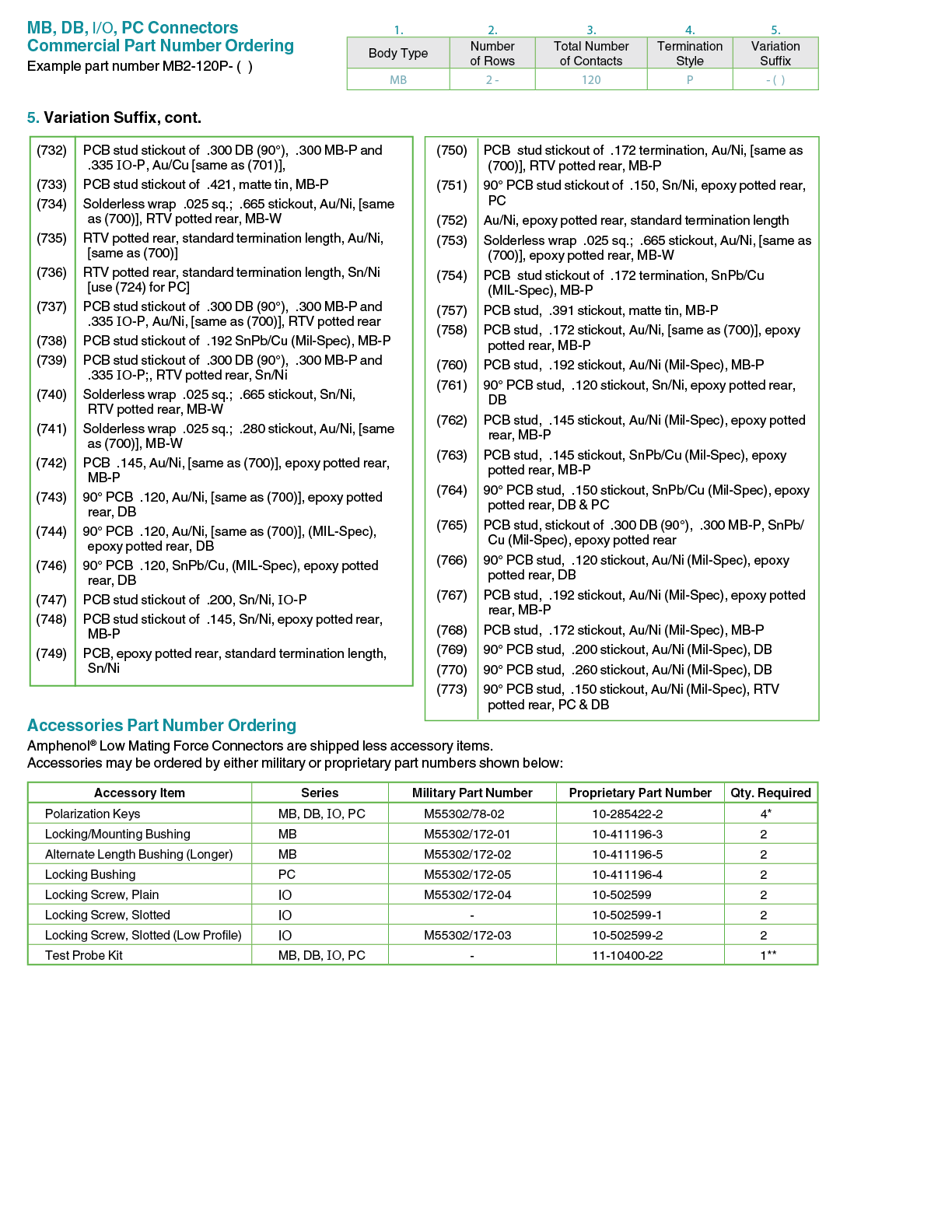

How to Order Guides

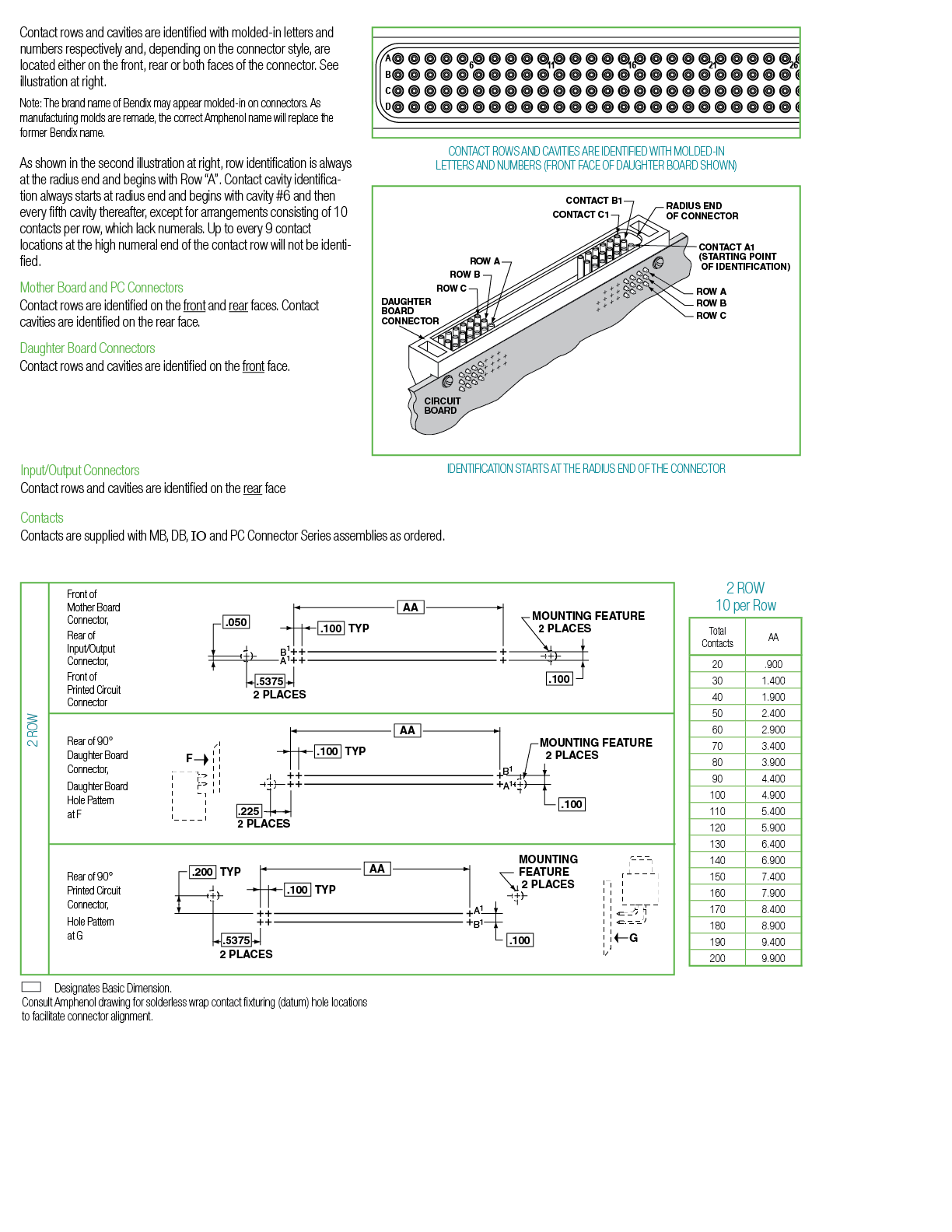

Row + Cavity ID, Contact Arrangements

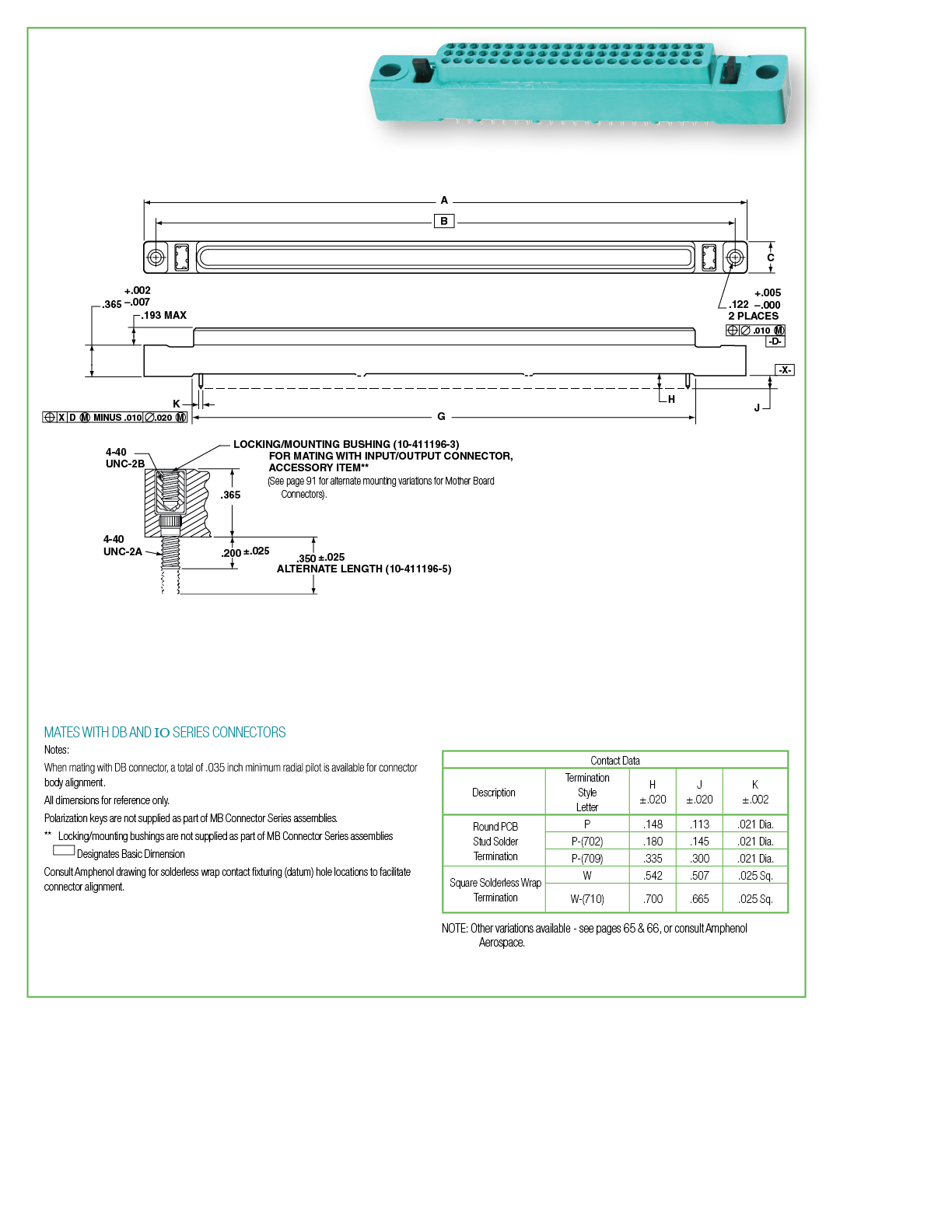

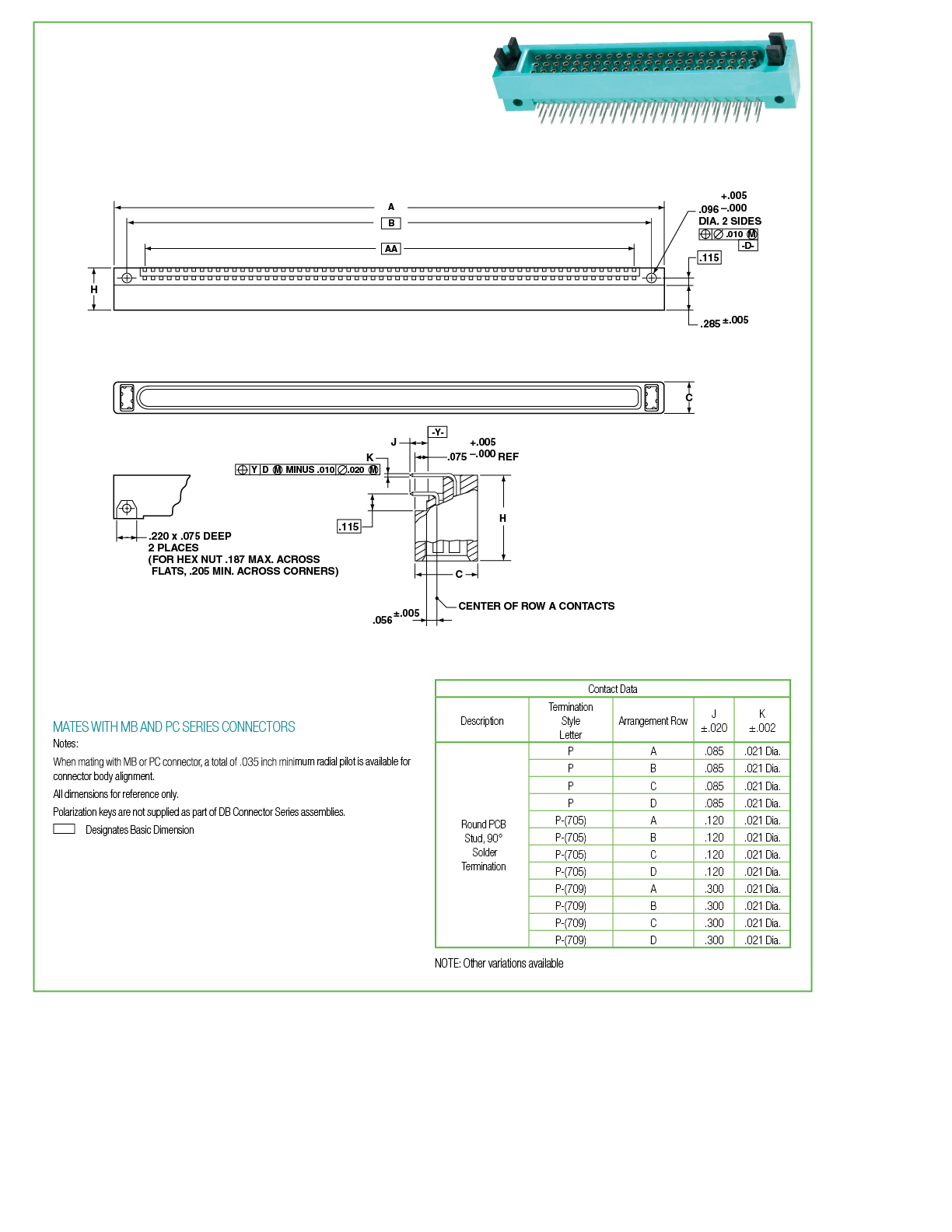

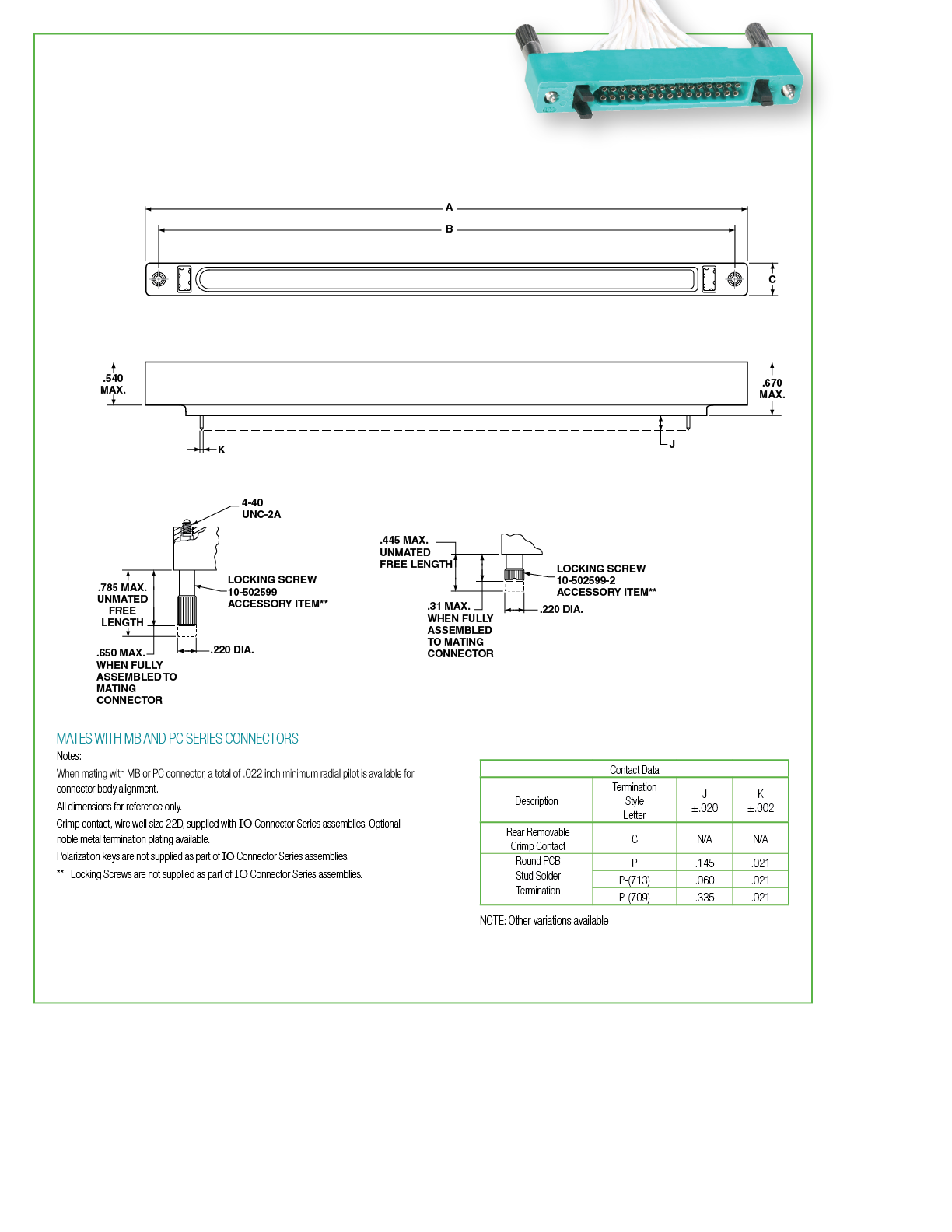

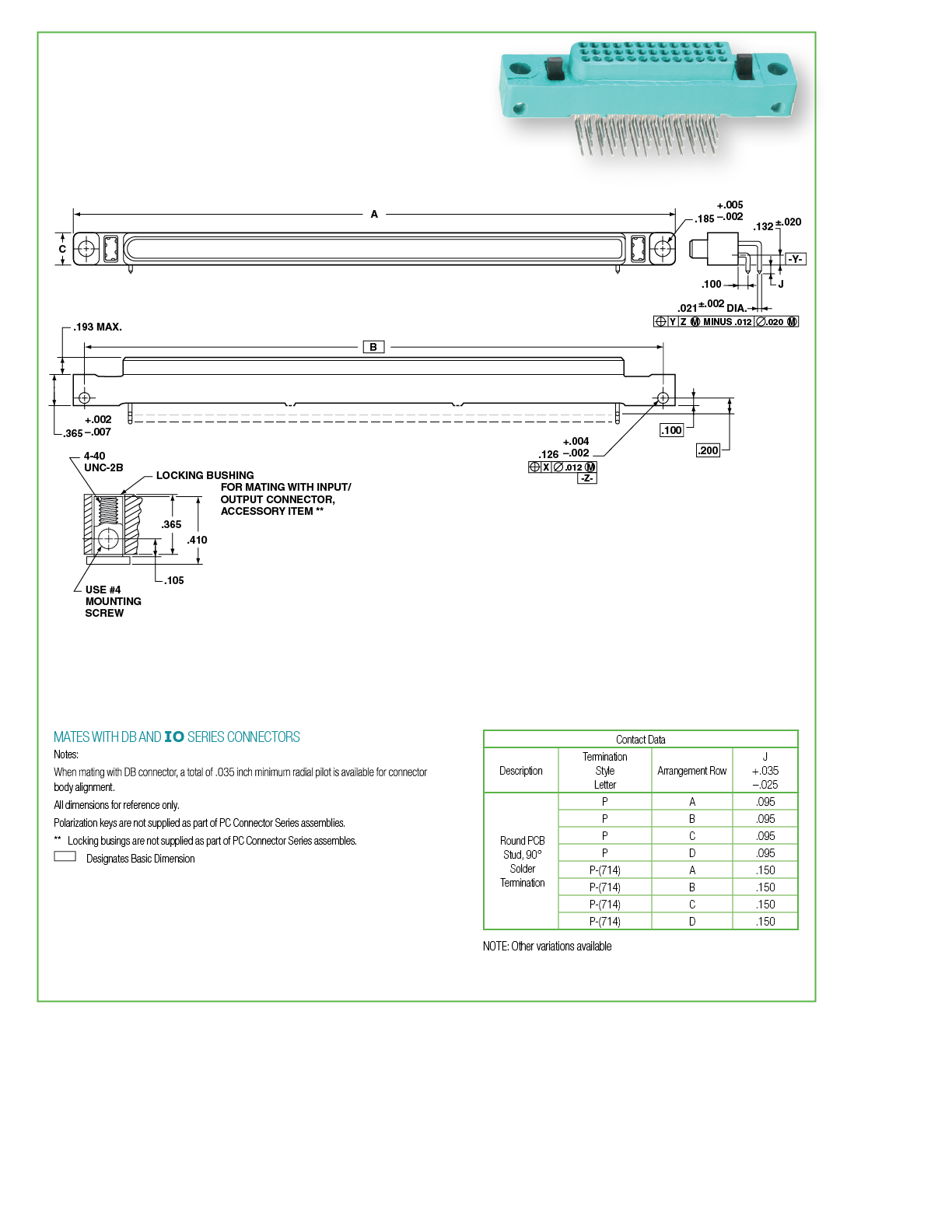

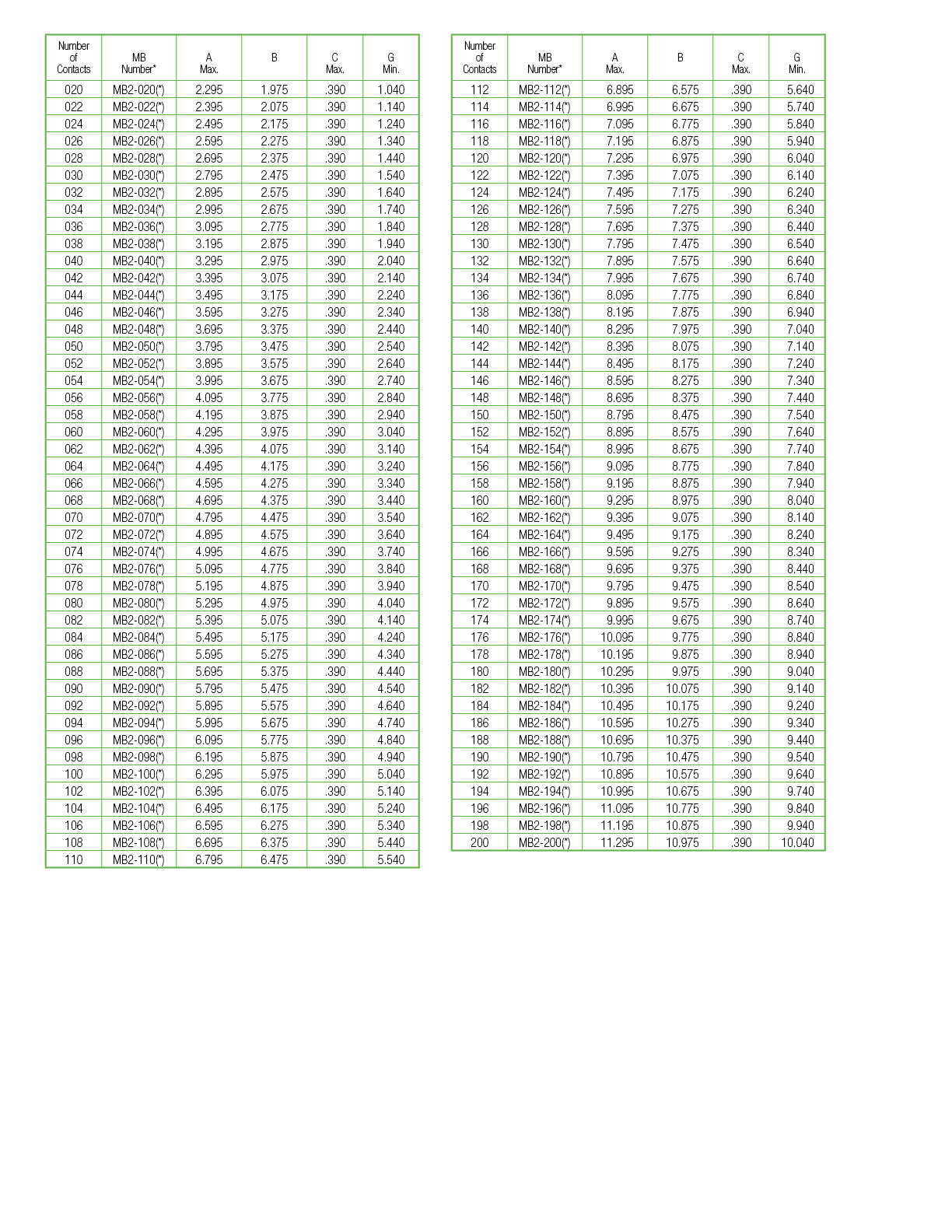

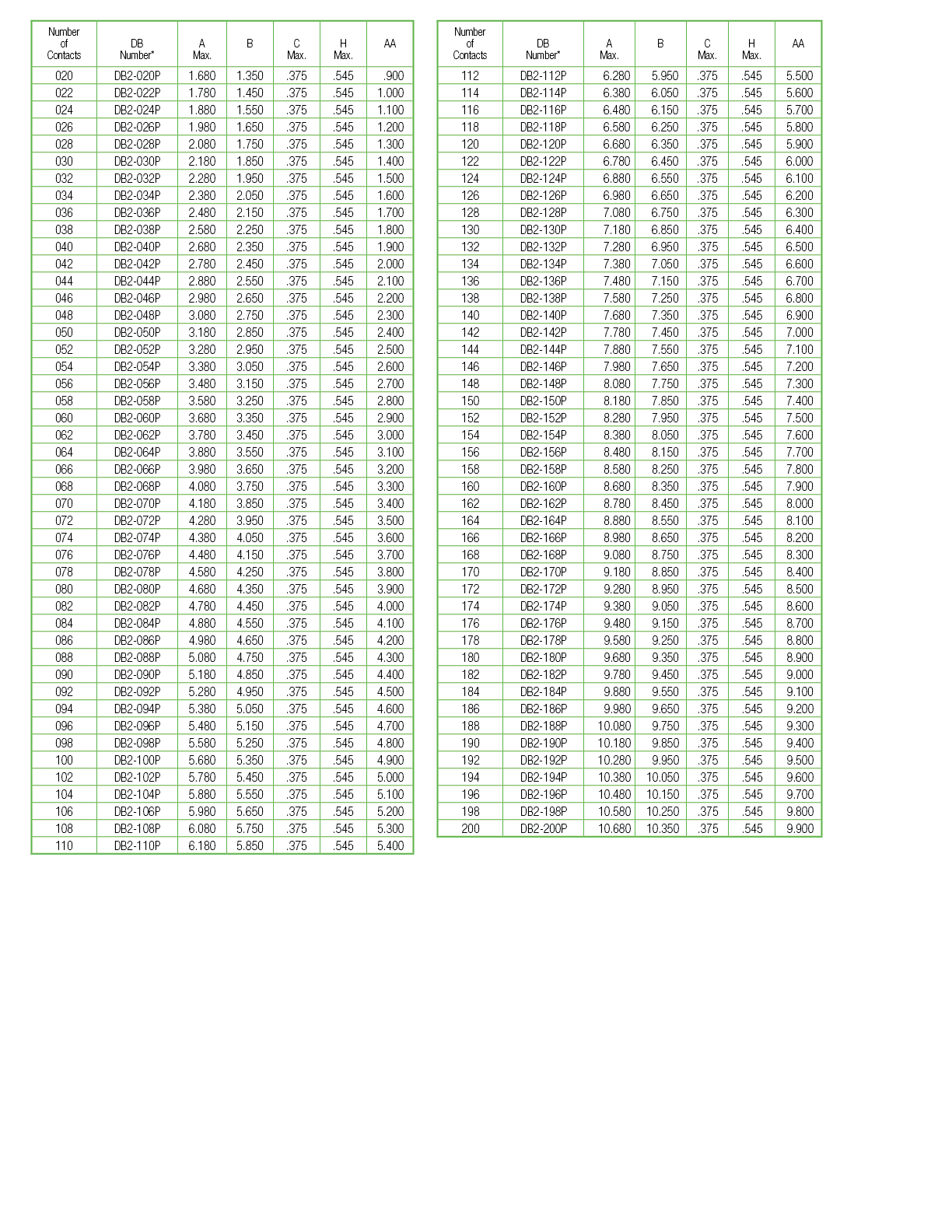

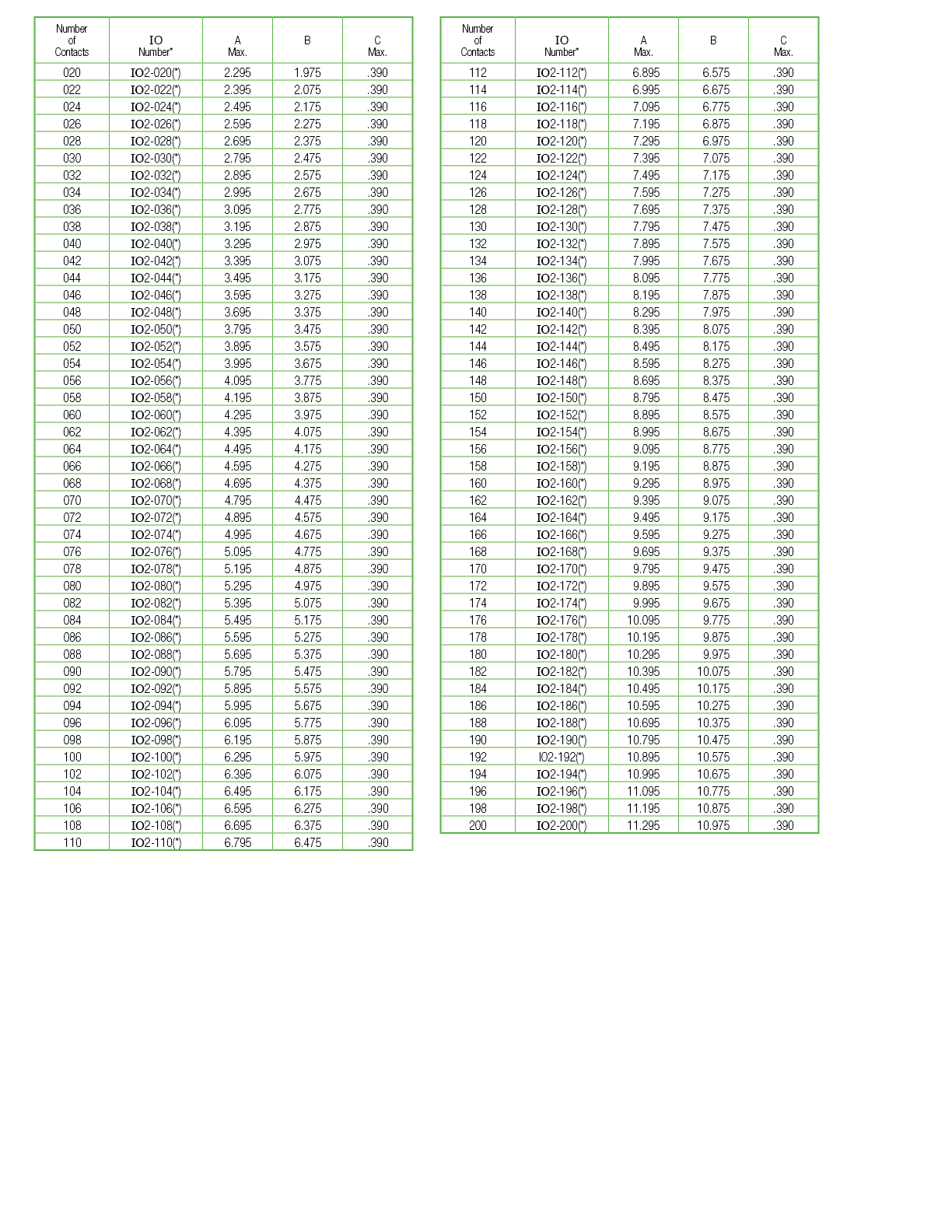

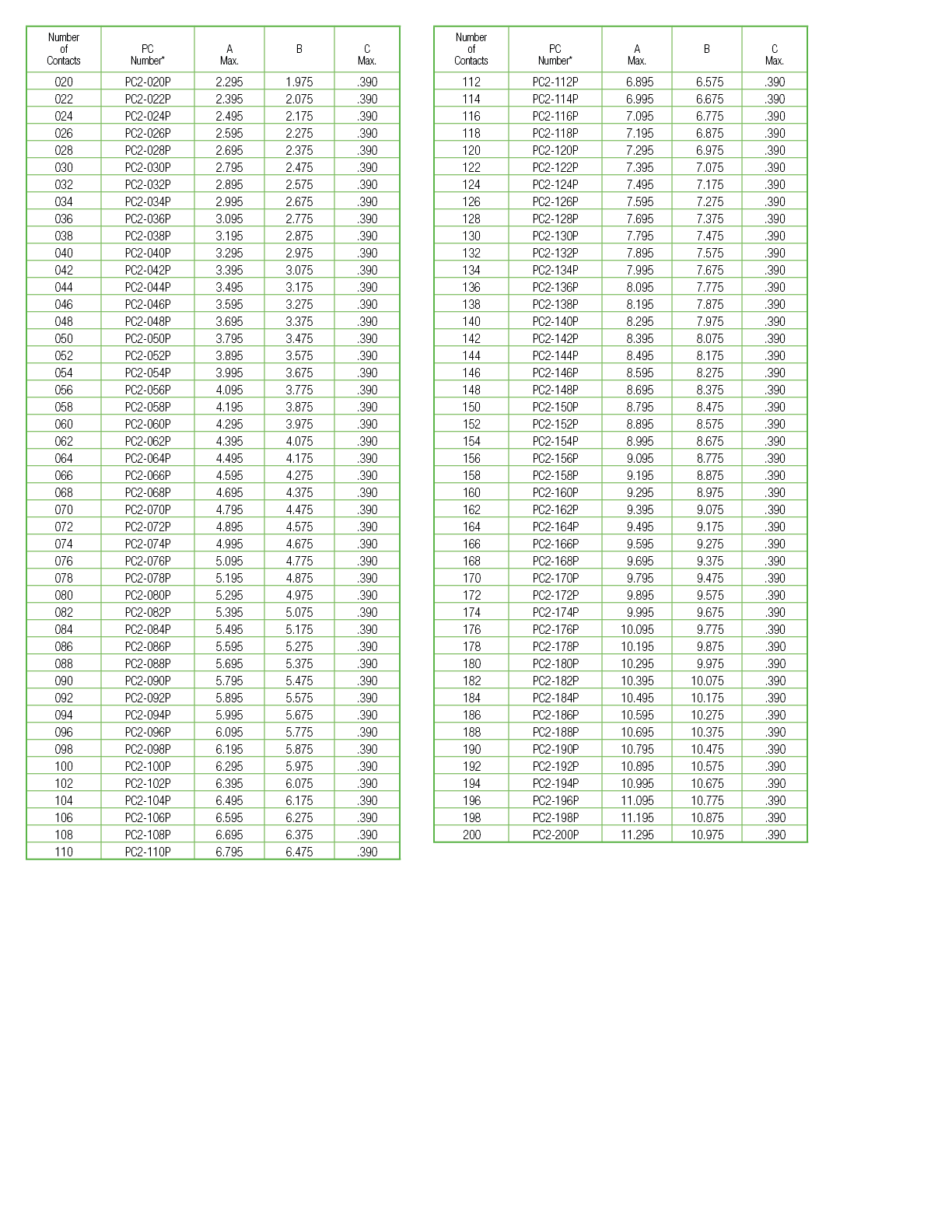

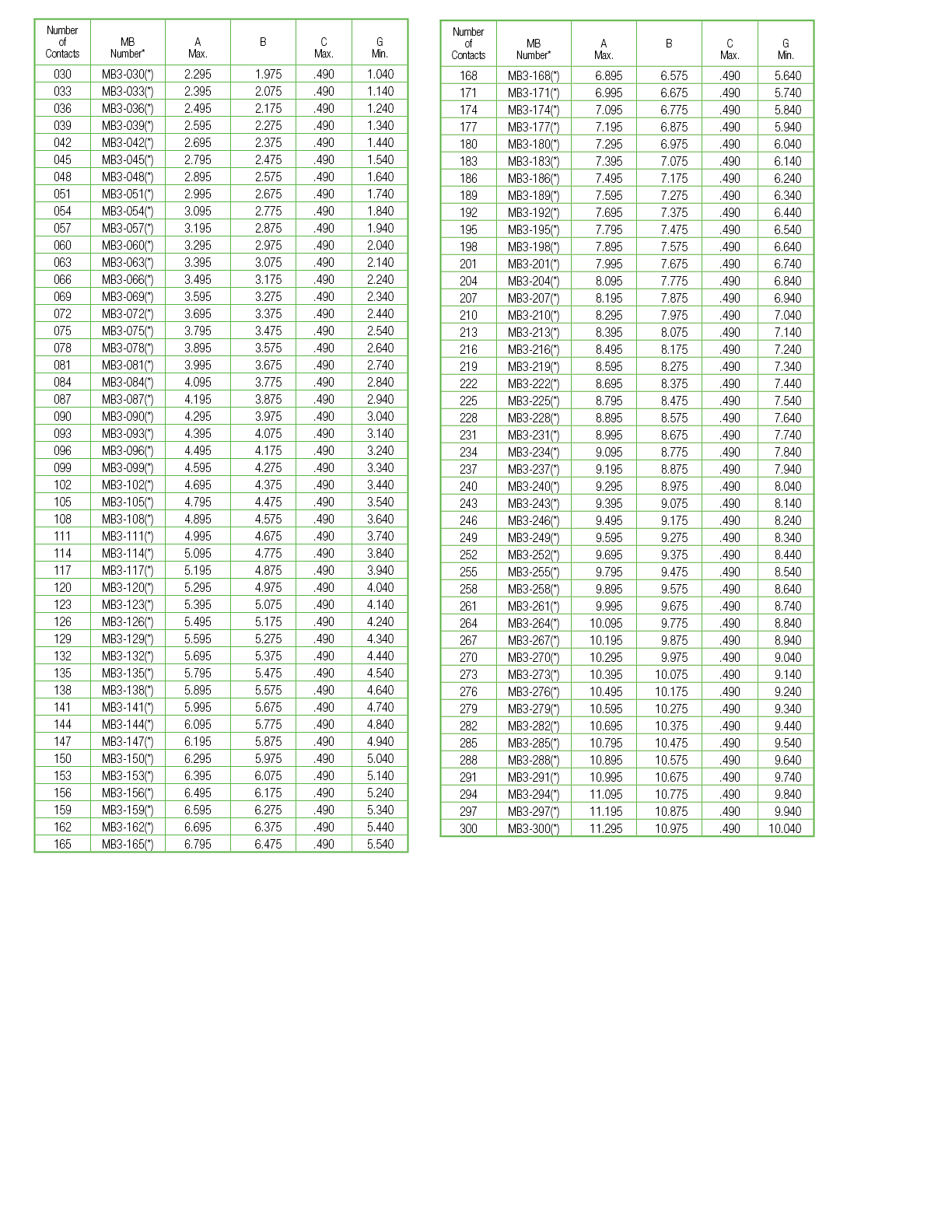

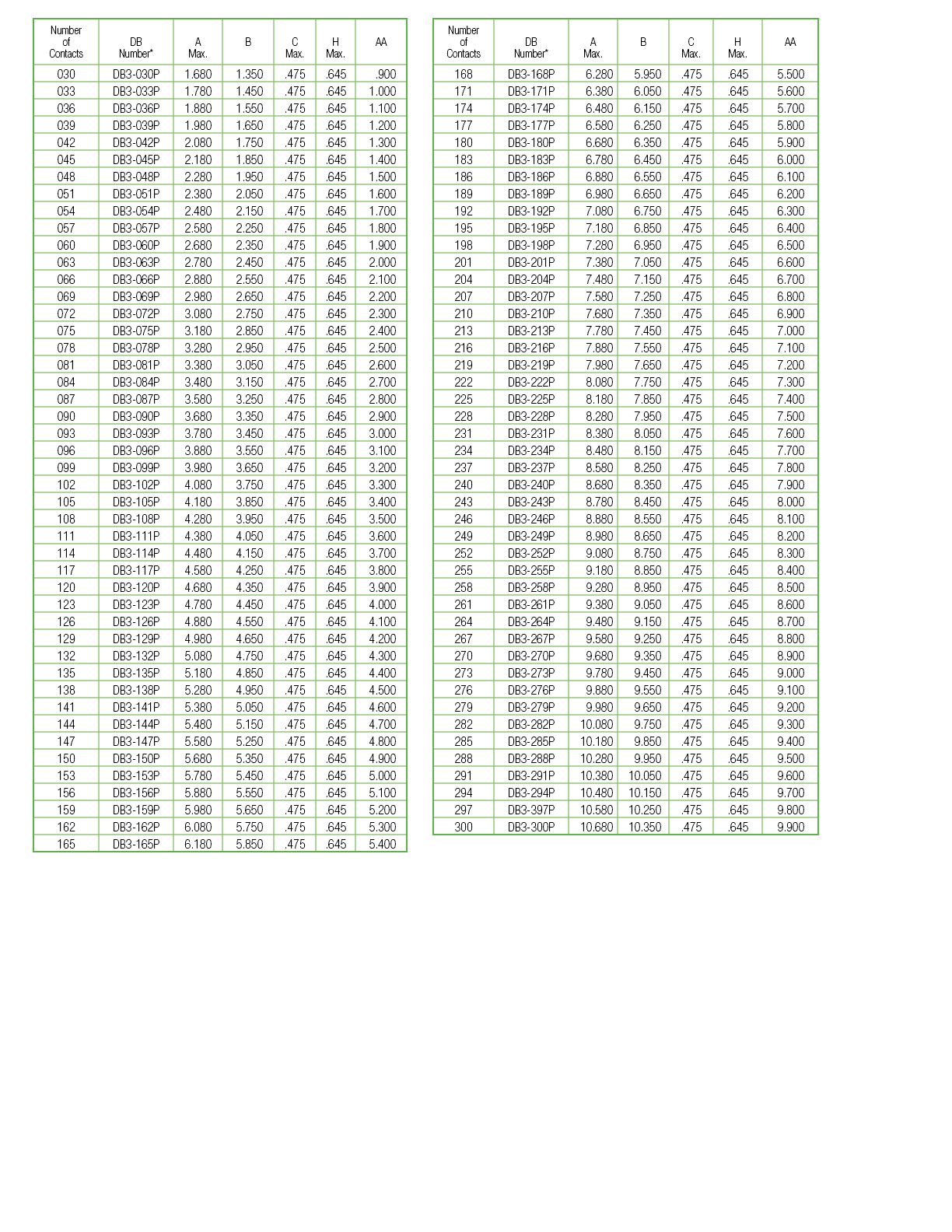

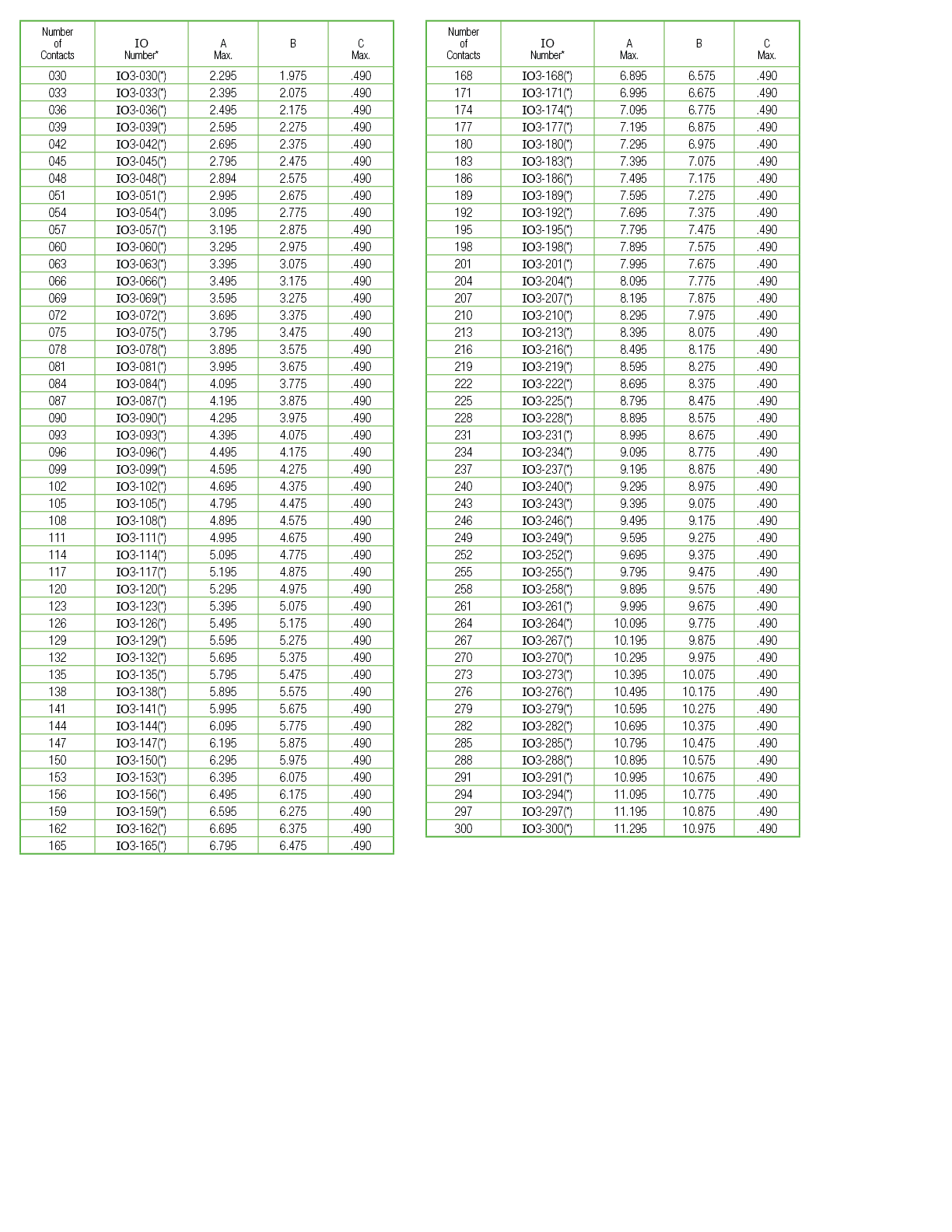

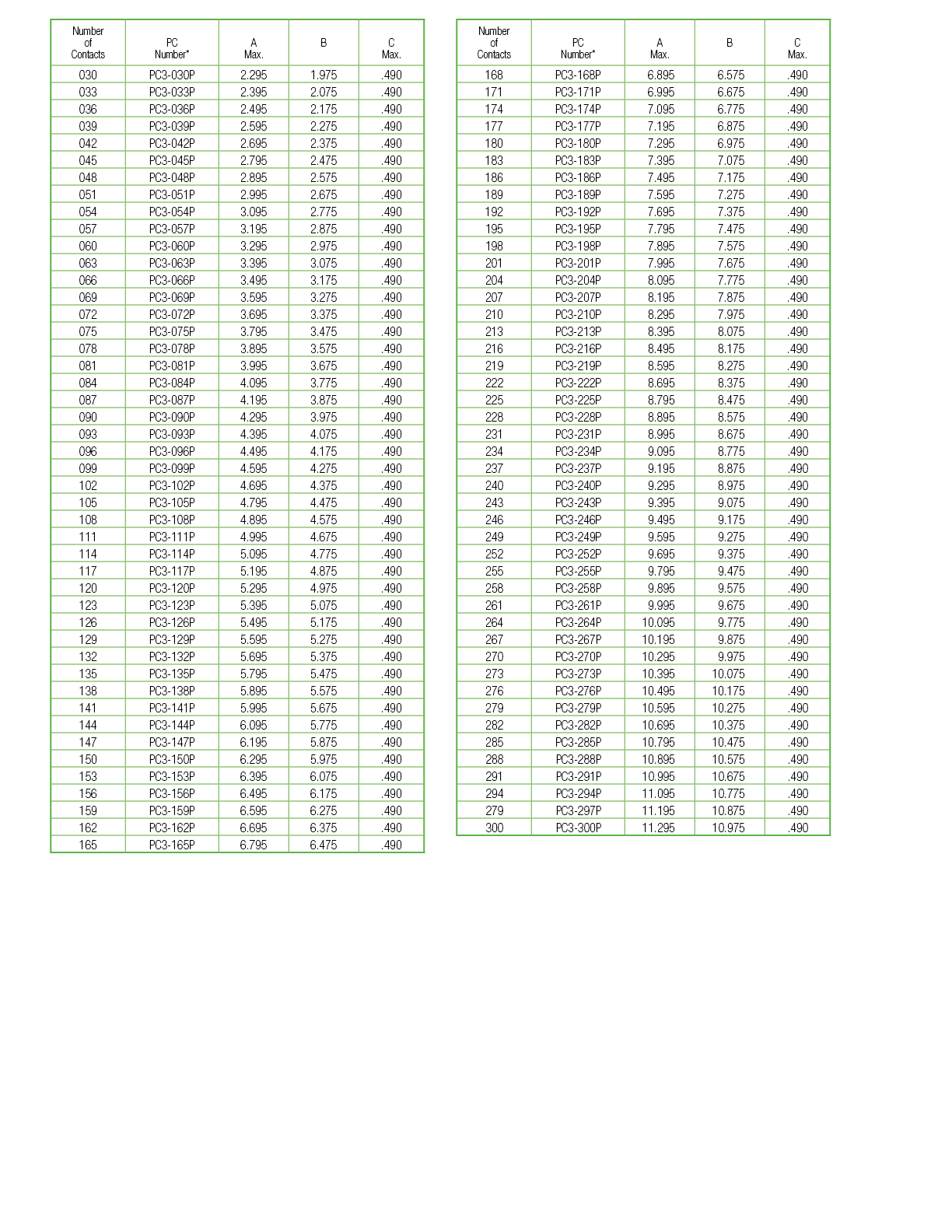

Connector Dimensions

2 Row Contact Arrangements

3 Row Contact Arrangements

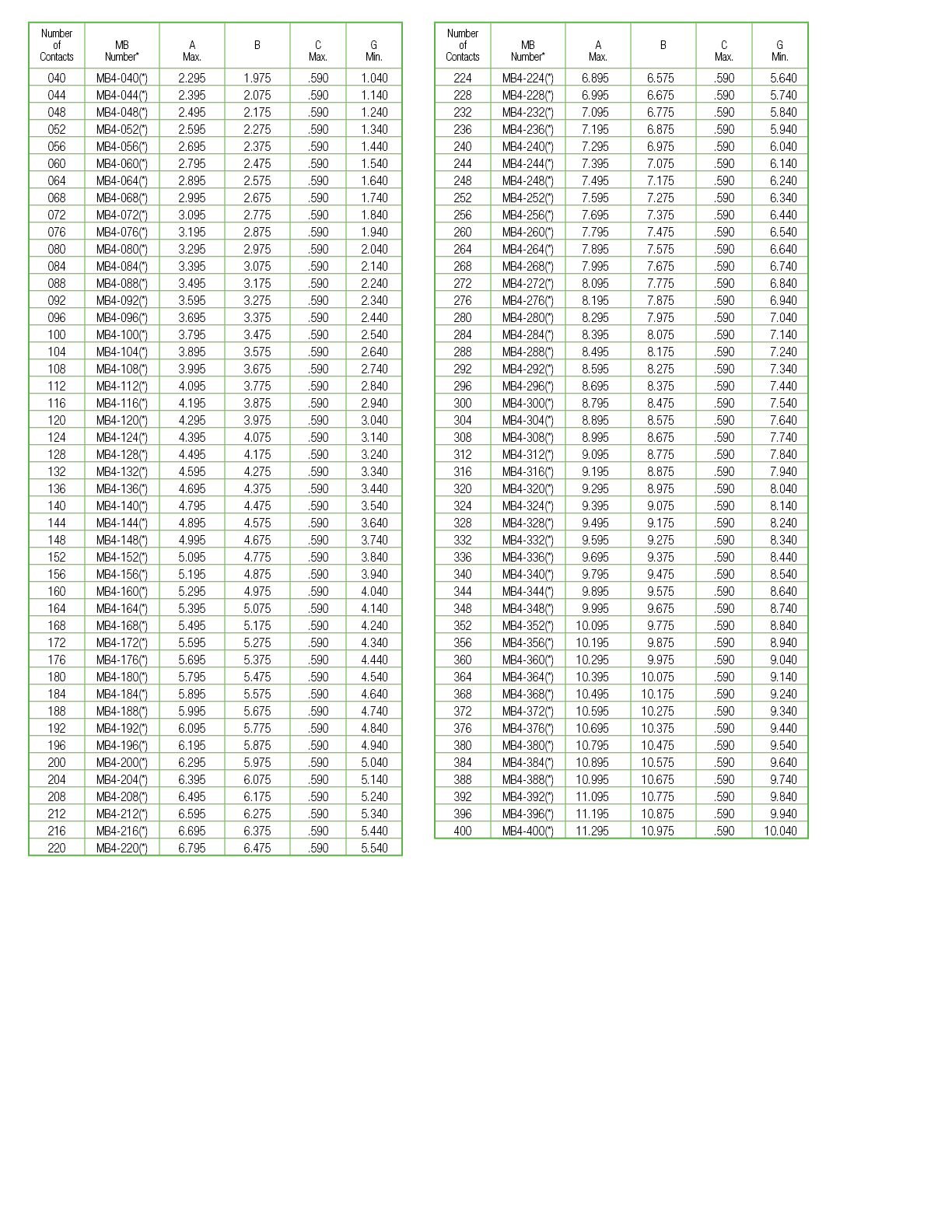

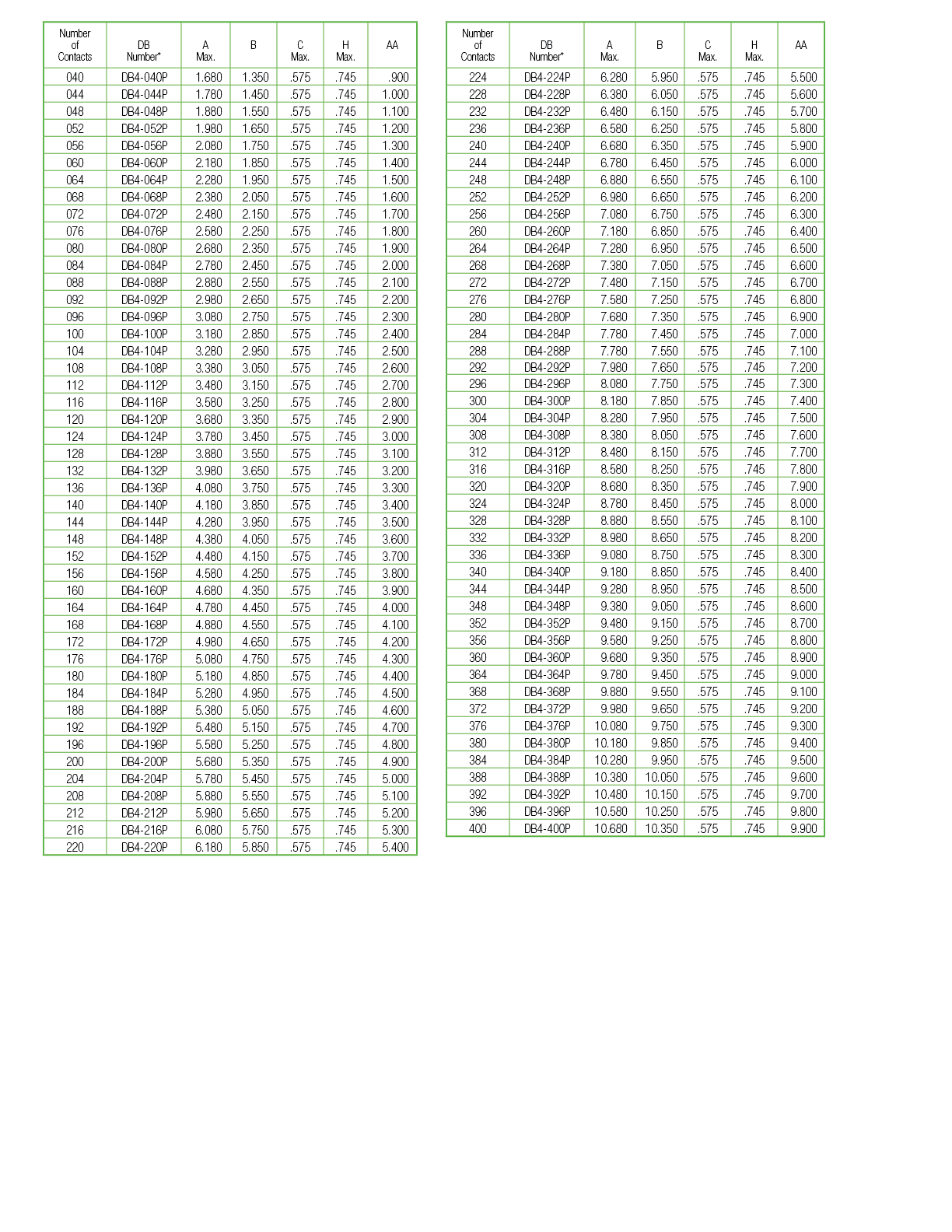

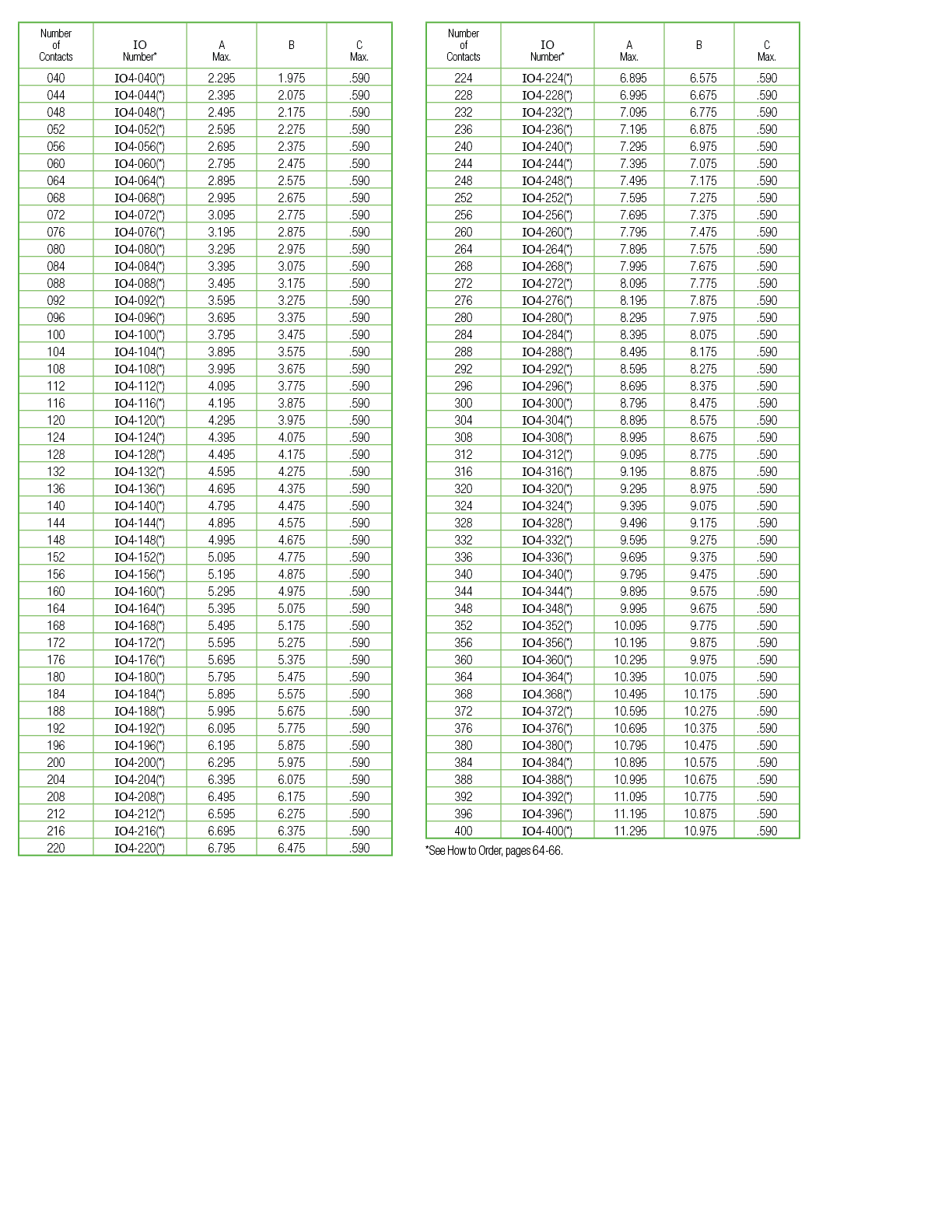

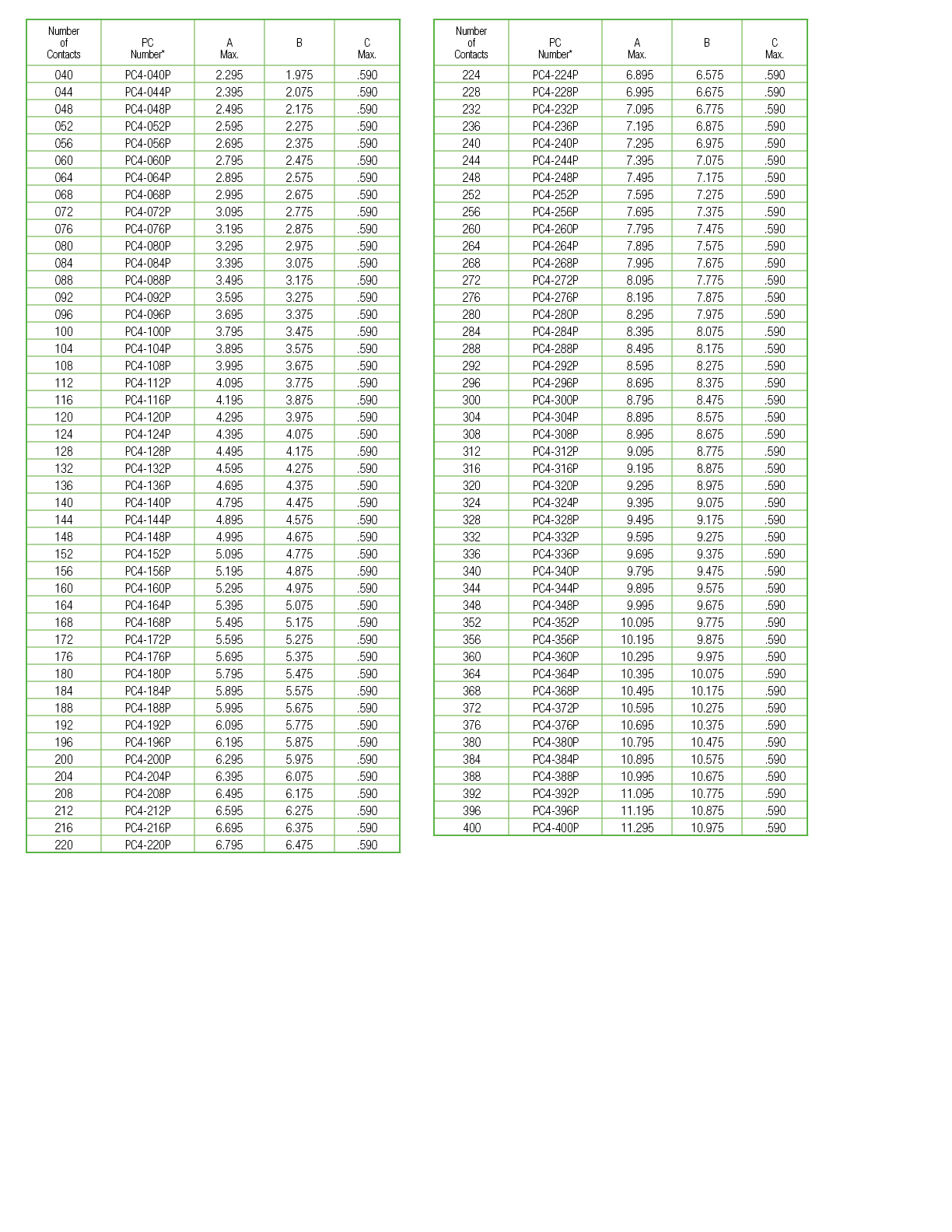

4 Row Contact Arrangements

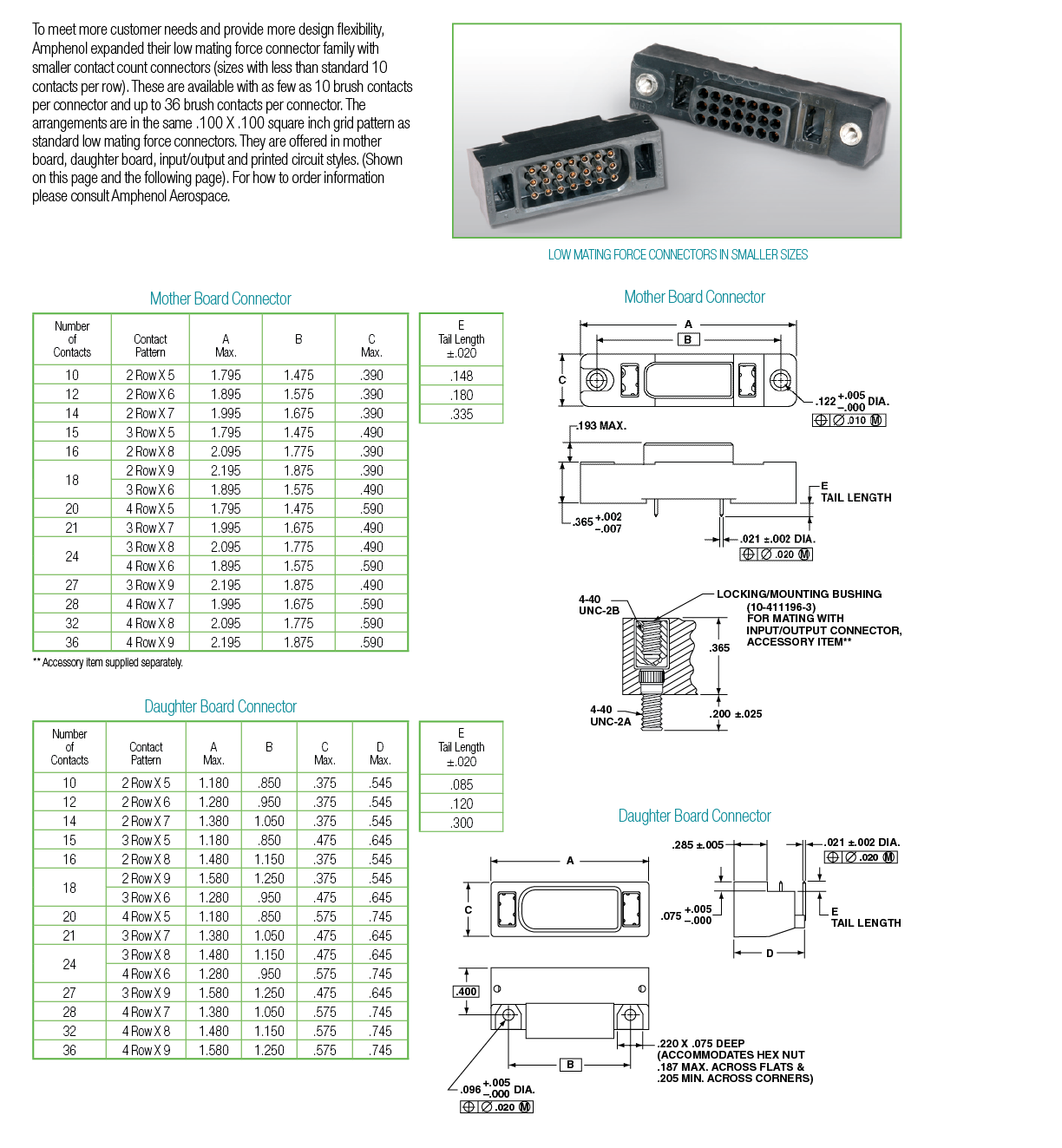

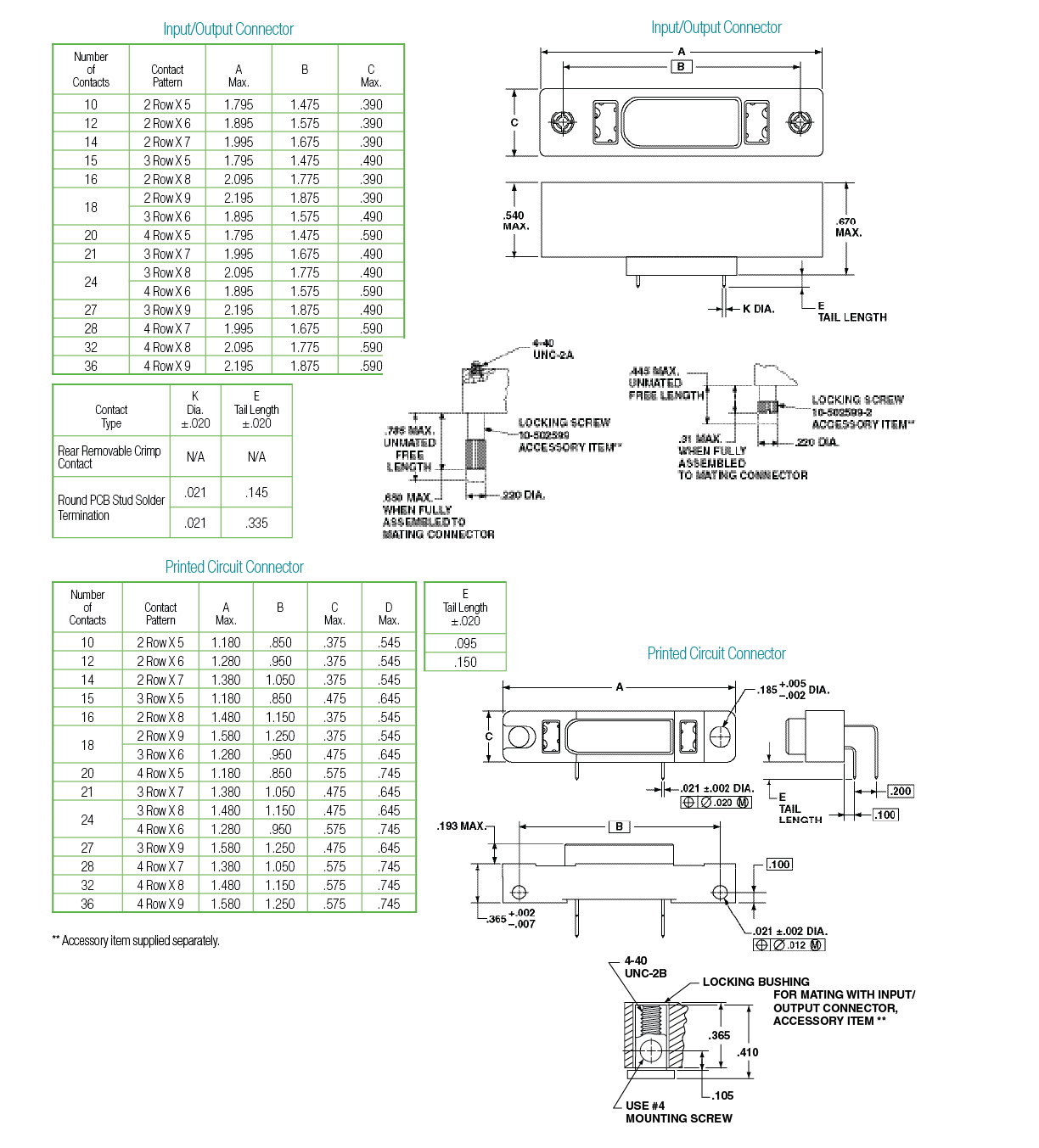

Smaller Size .100 x .100 Sq. Inch Grid

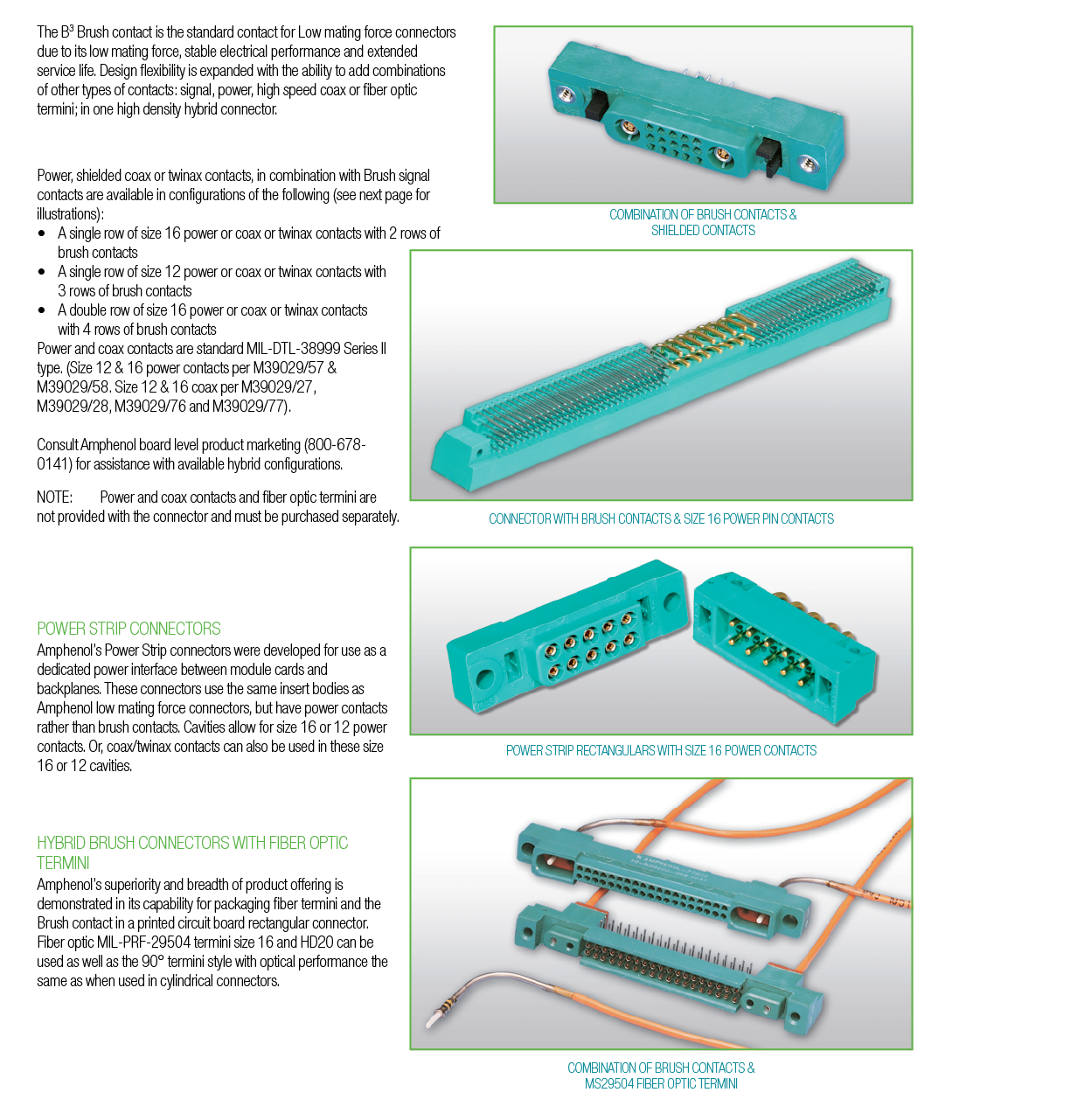

Hybrid Configurations

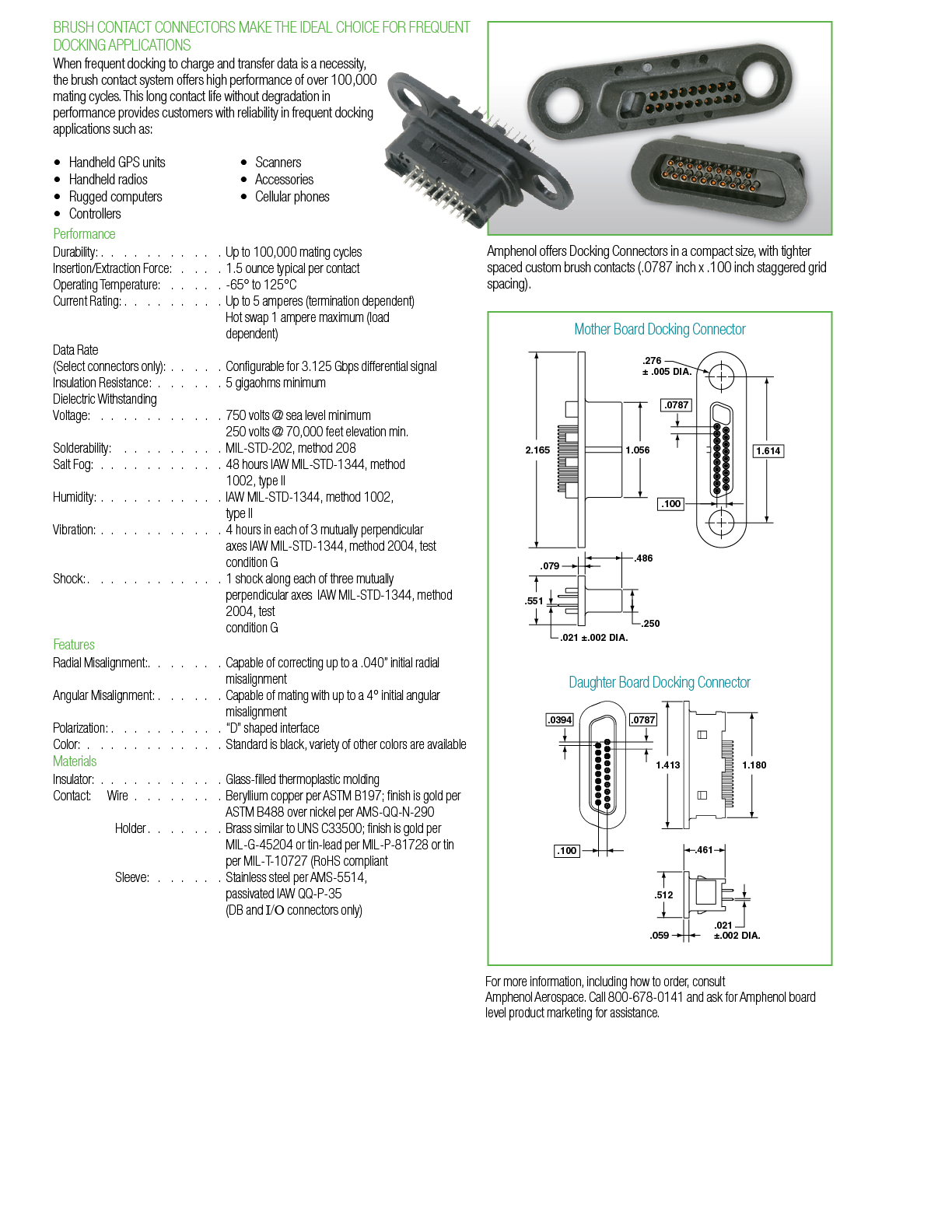

Docking Connectors

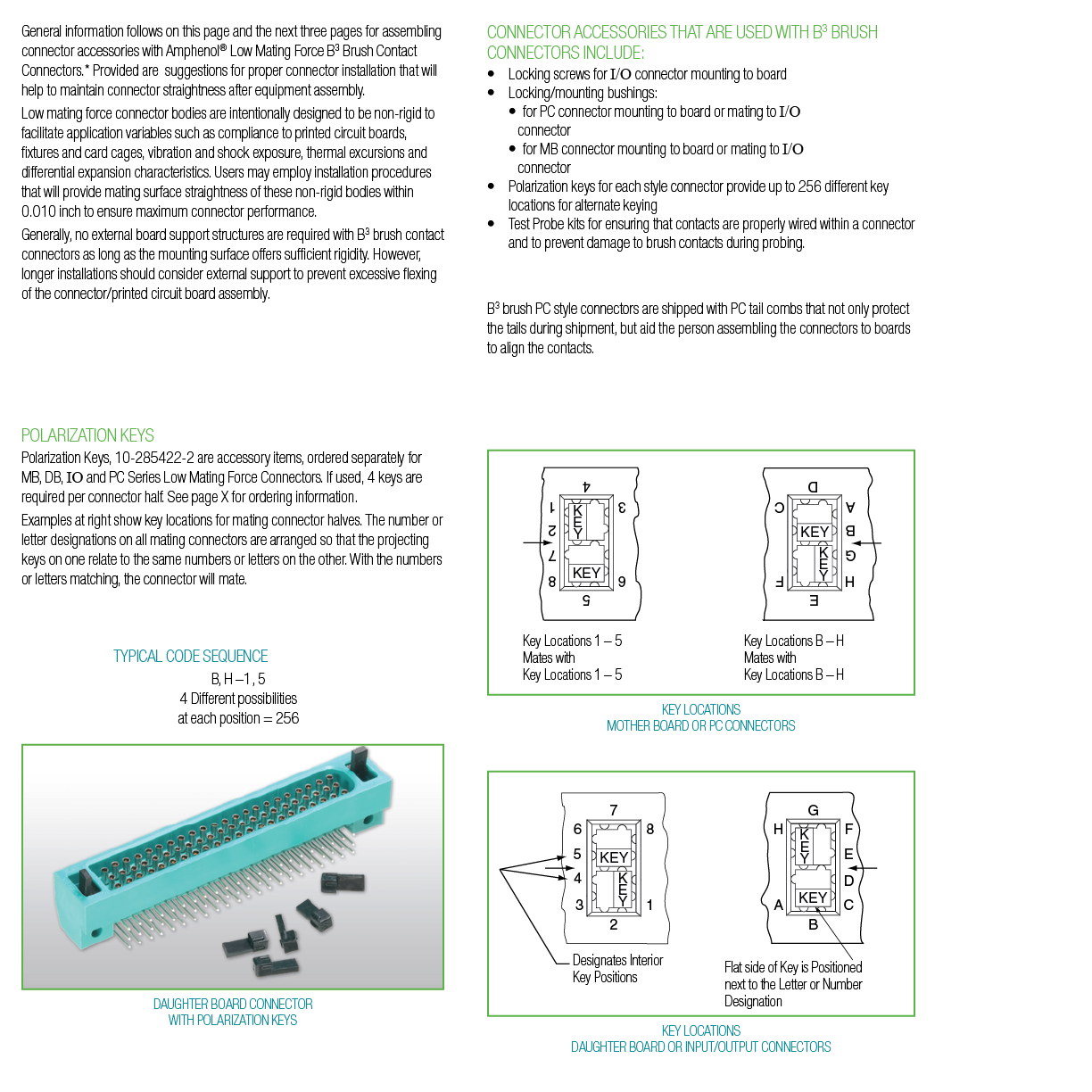

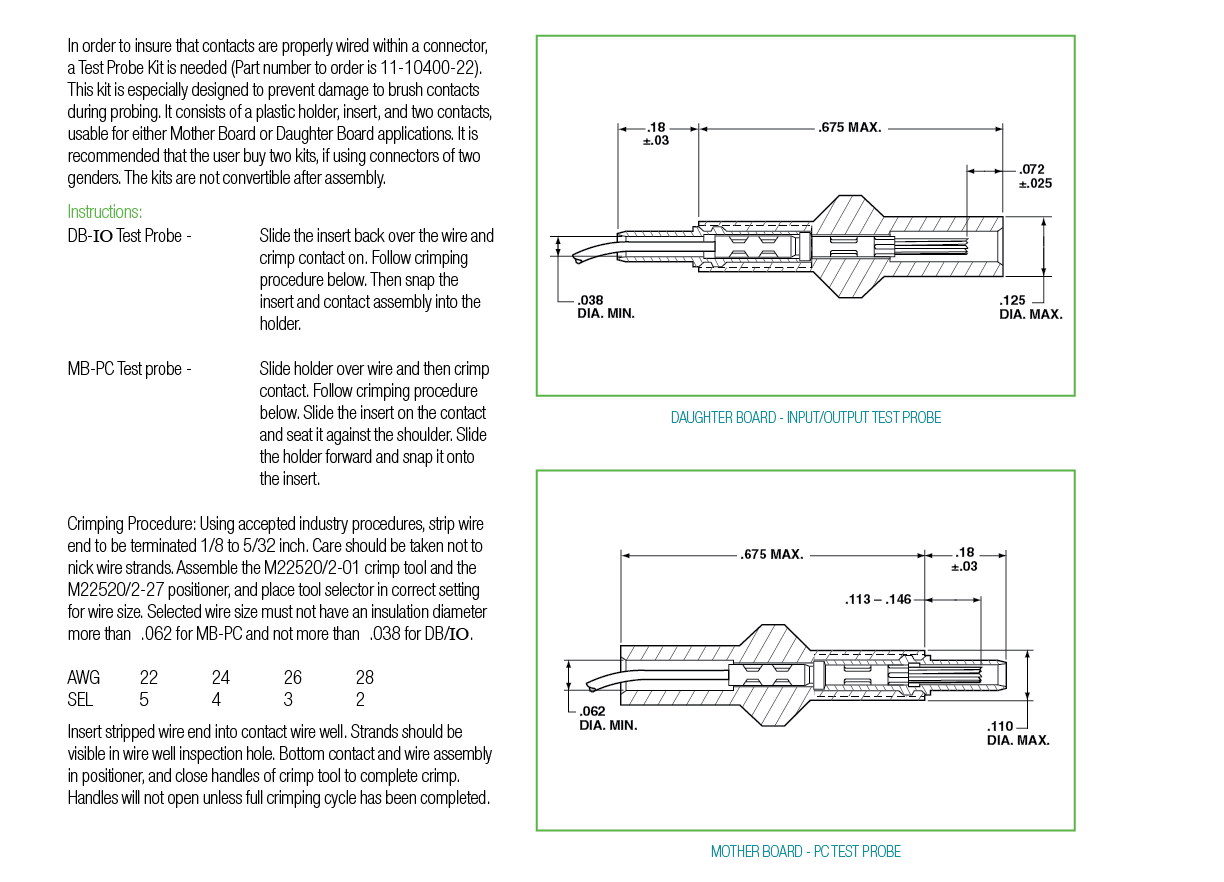

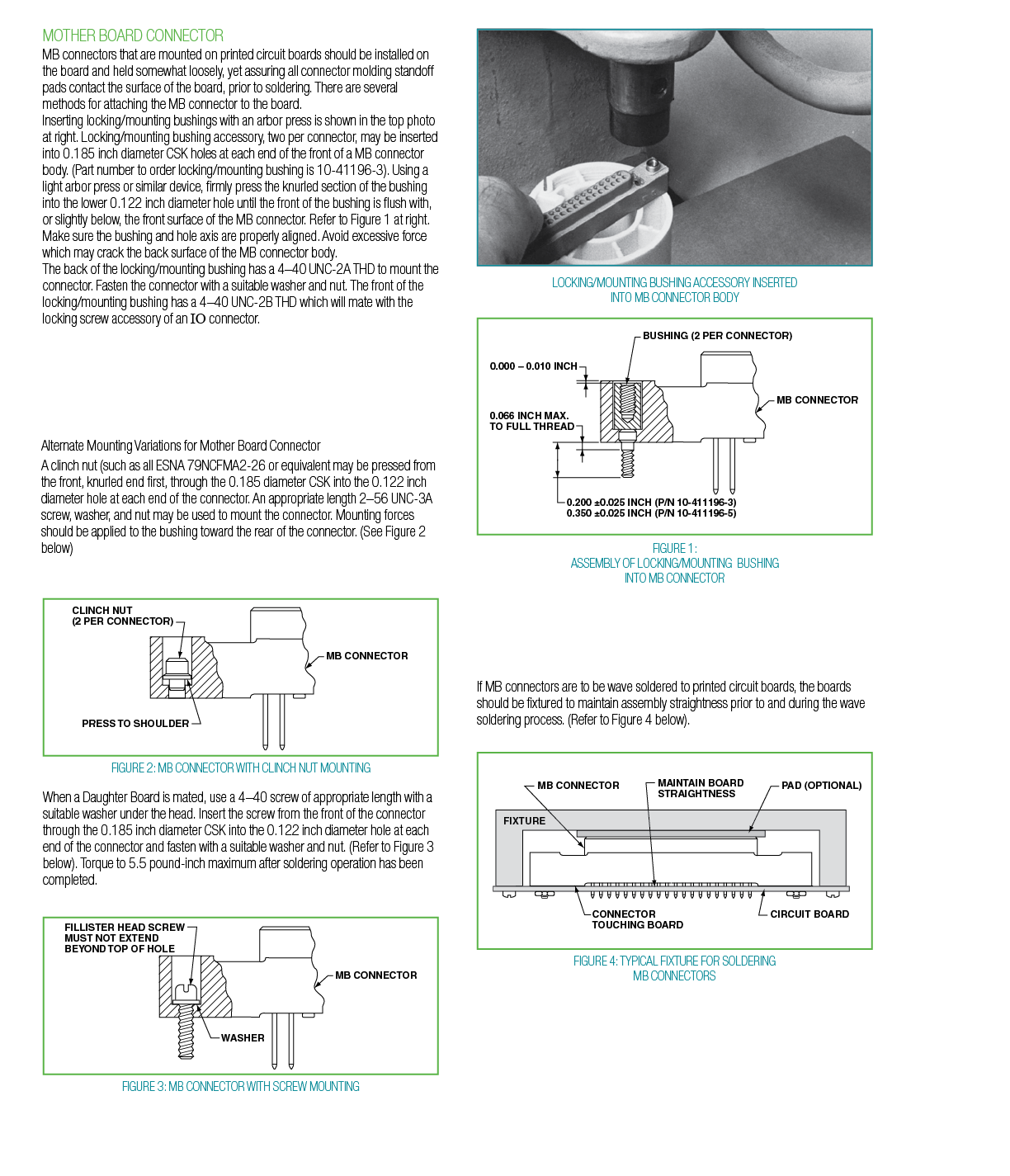

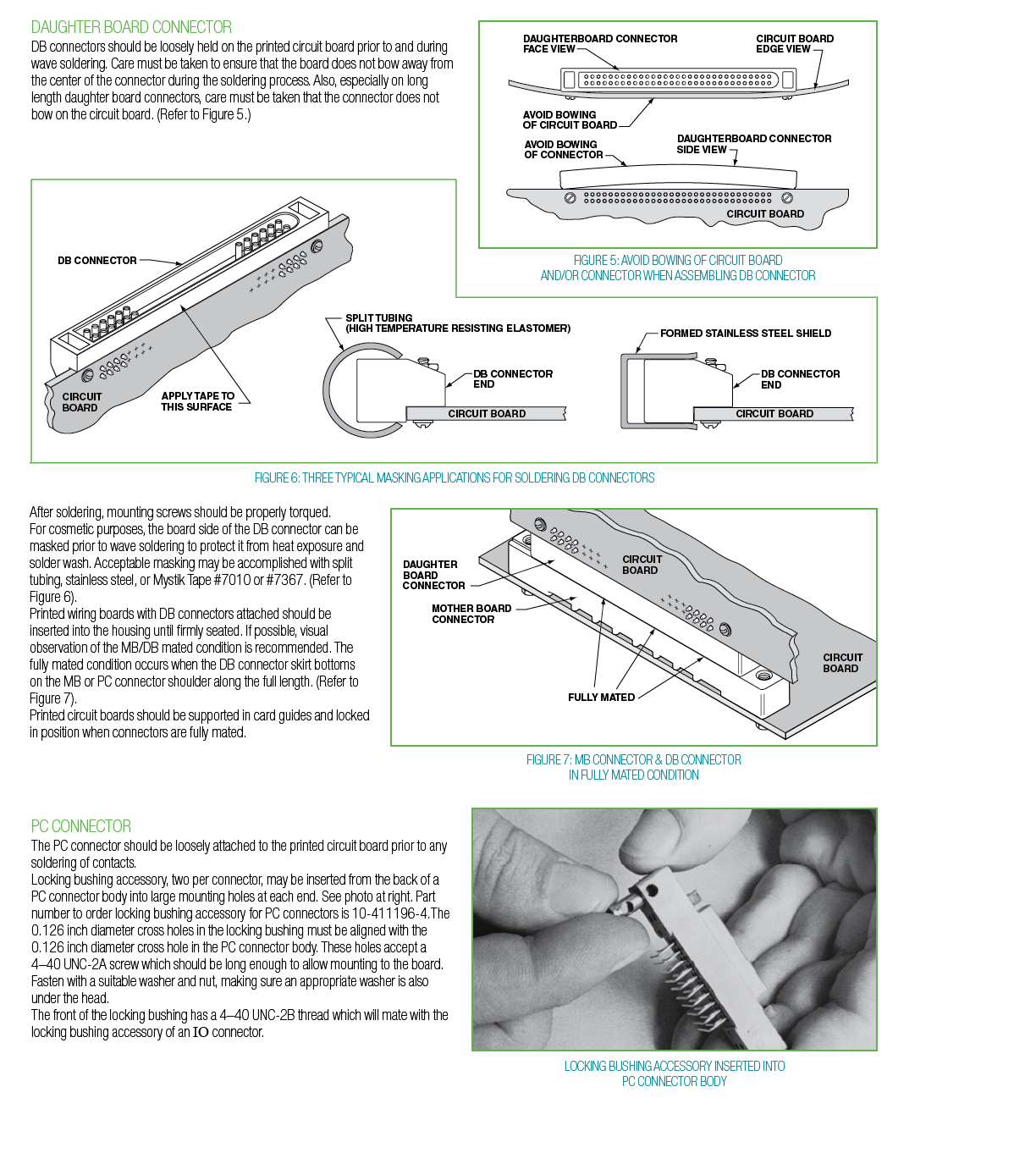

Accessories

Installation Instructions

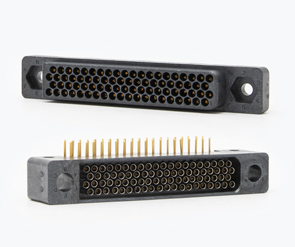

HDB3/HSB3

Incorporates a higher density contact pattern and lower mated height than Amphenol’s standard low mating force rectangular connectors.

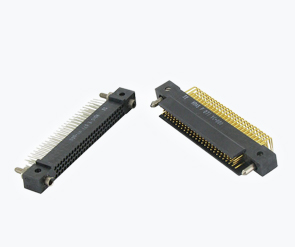

HDAS

HDAS rectangular connectors are the right high-density PCB connector when installation, cost and reliability must be considered.