VITA Connectors

Amphenol VPX Solutions

Amphenol VITA connectors are essential for applications that involve significant data transfers in harsh environments. We’ve innovated the VPX and OpenVPX standard by designing connectors that are ruggedized while also offering industry-leading speeds. Amphenol’s VITA line of products is suited for a variety of applications, including:

- Ground combat systems

- Commercial and military aerospace

- Missile defense

- Space data centers and other space systems

- Radar and sonar equipment

- Intelligence, surveillance, and reconnaissance systems

- Sensors, switches, and integrated processors

- Electronic warfare (EW) and C5ISR systems

- VPX single board computers

- Embedded computing

- Phased array radars

- Single processing computers

What is VITA?

VITA (VMEbus International Trade Association) is the working group responsible for the development and sustainment of VPX open standard computer bus technology that forms the backbone of Amphenol VITA connectors. Amphenol Aerospace is an active member of the VITA working group alongside other industry leaders in military aerospace and electronics manufacturing. Amphenol has played a prominent role in the development and promotion of VITA open-source technologies such as VPX.

VITA began in 1982 as the VMEbus Manufacturers Group and changed its name to the VMEbus International Trade Association (VITA) a few years later. Ultimately, the name was shortened to just VITA in 2005. Throughout its existence, VITA has developed and advanced a variety of open architecture standards and products, including VPX.

What is VPX?

VPX is an open architecture specification that’s wide in scope. But generally, it refers to a family of computer bus technologies that utilize 3U and 6U switched fabric formats, among other features. The VPX standard is an industry-standard technology for embedded computing systems that require especially fast data processing speeds, such as those common in modern commercial and military technologies.

The first VPX specification, known as VITA 46, emerged in 2004 and became a standard with the American National Standards Institute (ANSI) in 2007. Multiple VPX specifications have been added to the VPX family of technologies since stemming from the founding of VITA 46 architecture.

The VPX standard necessitates a variety of technologies, including:

- 3U and 6U formats

- High-speed backplane and module connectors rated up to 25 Gb/s+

- Choice of high-speed serial fabrics

- PMC and XMC mezzanines

- Hybrid backplanes to accommodate VME64, VXS, and VPX boards

- Passed VITA 72 vibration level testing with BER monitoring.

Amphenol R-VPX connectors, or ruggedized VPX, adhere to stringent VPX criteria defined in VITA 46 and are optimized for harsh environments with a multipoint contact system.

OpenVPX improves the base technology by addressing interoperability points within standard VPX architecture. OpenVPX maintains VITA specifications, speed, and performance, but with a defined set of system architectures that allows seamless integration with different modules and backplanes. The introduction of OpenVPX cuts down on the need for developers to create custom system architecture for applications where they wish to apply VPX technology. This innovation reduces development times while decreasing costs and design challenges.

OpenVPX arose when the U.S. Department of Defense and other users began to prioritize open standards and interoperability practices throughout the defense industry. A notable driver was the MOSA memorandum issued by the DOD in Jan. 2019.

Amphenol’s R-VPX connector series has passed VITA 72 vibration level testing with BER monitoring.

This stringent testing protocol assesses how well a VITA component can withstand extreme vibrations over an extended period. Amphenol’s R-VPX underwent a battery of random and sine vibrations according to the 6U VITA 72 test plan in addition to mechanical shock testing. Throughout the testing sequences, the connectors did not sustain any damage or BER failures and displayed acceptable LLCR levels per the VITA 72 study group standards.

Amphenol’s R-VPX connectors, and by extension our EVO and EVO2 connectors due to their identical mating interface, are proven to sustain structural integrity and functionality under intense vibrational circumstances and are excellent for applications where extreme vibrations are expected.

See our Product Configurator for available drawings and 3D models.

VITA Frequently Asked Questions (FAQ)

What Are VITA Connectors?

VITA connectors are high-performance, ruggedized board-level connectors that adhere to the open standards developed by VITA for embedded computing systems. These connectors are designed for use throughout embedded systems operating in harsh environments and support high-speed data, power, and signal transfer.

VITA connectors are commonly used throughout:

- VPX and OpenVPX systems (modular computing architectures)

- VMEbus systems (older bus-based computing architecture)

- FMC (FPGA Mezzanine Card) modules

- XMC (Switched Mezzanine Card) modules

What Are the Different Types of VITA Standards?

Some of the different types of VITA standards include:

VITA 46 – VPX

Defines a high-speed, ruggedized backplane architecture using serial fabrics like PCIe, Ethernet, and RapidIO. It replaces the legacy parallel VMEbus and supports modular, high-performance computing in harsh environments throughout defense and aerospace.

VITA 65 – OpenVPX

Builds on VPX by standardizing module, slot, and backplane profiles to ensure interoperability between vendors. It defines a system-level framework for scalable and modular embedded computing platforms in mission-critical systems.

VITA 62 – VPX Power Supplies

Standardizes modular power supply units that fit into VPX slots for reliable and ruggedized power delivery. These supplies support multiple voltages and are designed for harsh embedded environments.

VITA 78 – SpaceVPX

Adapts VPX for space-grade applications, emphasizing redundancy, fault-tolerance, and radiation resistance. It's used in satellites, deep-space missions, and other spaceborne embedded computing systems.

VITA 66.1 and VITA 66.4– Optical MT Ferrules

Specifies passive, blind-mate optical connectors using MT-style ferrules (MTP/MPO) between VPX modules and backplanes. Ideal for EMI-immune, high-density fiber links in ISR, radar, and sensor systems. VITA 66.4 specifies a half-width variant for space-saving purposes.

VITA 46.30 – High-Speed VPX

Extends VPX to support signal rates up to 25+ Gbps per lane using advanced backplane connectors. It's essential for modern data-heavy applications like AI, 100G Ethernet, and PCIe Gen5 in rugged environments.

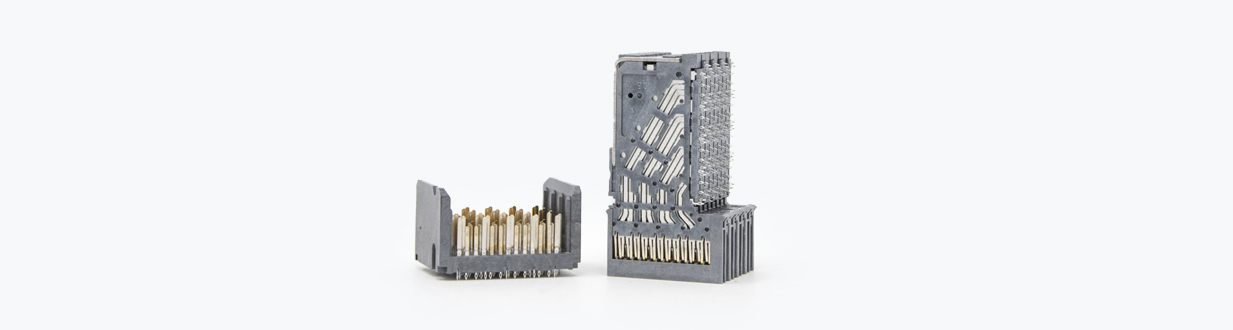

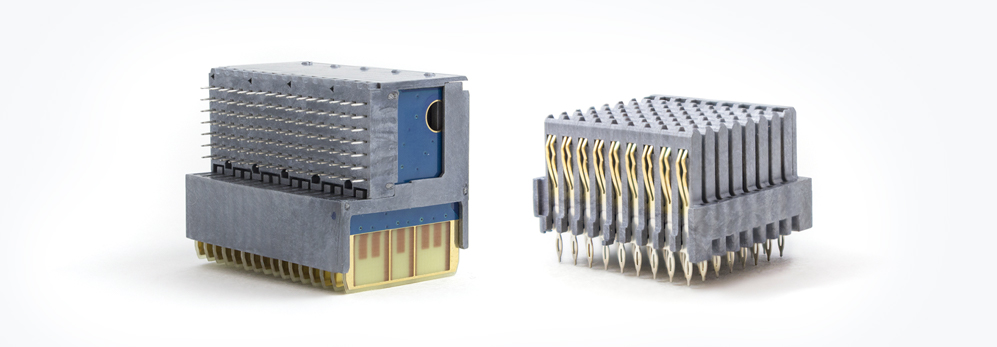

R-VPX VITA 46 Connector System

What is the R-VPX VITA 46 Connector System?

The R-VPX VITA 46 Connector System is a high-performance interconnect solution designed for VPX (VITA 46) applications. It supports high-speed data transmission, rugged environments, and complies with ANSI/VITA 46 standards. These connectors are designed for use in board-level connections in embedded systems throughout harsh environment military and aerospace applications.

What are the key features of R-VPX VITA 46 connectors?

- Qualified to VITA 46 for OpenVPX applications

- Supports high-speed protocols such as 1000BASE-KX, 10GBASE-KX4, 10GBASE-KR10, 40GBASE-KR4, PCIe (Gen 1–5), Serial RapidIO, and other multi-gigabit serial links

- Available in 3U and 6U form factors

- Ruggedized for harsh environments

- Ensures signal integrity and low bit error rates

What applications are R-VPX VITA 46 Connector Systems used for?

R-VPX is commonly used throughout military and defense systems, avionics, high-performance embedded computing (HPEC), and ruggedized computing.

Does the VITA 46 connector support multiple Ethernet links?

Yes. VPX/OpenVPX architectures can support multiple Ethernet links depending on the slot profile and backplane design. R-VPX supports common Ethernet implementations used in VPX systems, including 1000BASE-KX and 10GBASE variants.

What is the difference between VITA 46 and VITA 65 (OpenVPX)?

VITA 46 (VPX) defines the base mechanical and electrical standards for VPX connectors, while VITA 65 (OpenVPX) builds on VITA 46 by adding system-level profiles for interoperability. The R-VPX connector complies with VITA 46.

Are these connectors backward-compatible with older VPX systems?

Yes, the R-VPX connectors maintain backward compatibility with legacy VPX systems while supporting newer high-speed protocols.

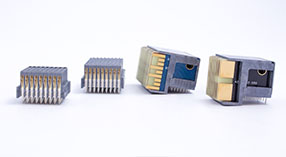

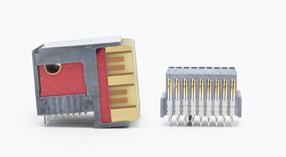

R-VPX Evolution 2.0 VITA 46.30 Connectors

What are R-VPX Evolution 2.0 VITA 46.30 connectors, and how do they differ from VITA 46.0?

R-VPX Evolution 2.0 connectors are VITA 46.30-based VPX interconnects designed for higher data-rate backplanes. They support speeds in excesss of 25 Gb/s and are designed to reduce crosstalk and improve signal integrity for next-generation VPX system speeds. They are also intermateable with existing/legacy VITA 46 connectors, while PCB designs must follow the appropriate VITA 46.30 footprint requirements.

What are the key benefits of Amphenol’s R-VPX Evolution 2.0 VITA 46.30 connectors?

- High Data Rates: Supports speeds in excess of 25 Gbps.

- Backward Compatibility: Intermateable with legacy VITA 46.0 connectors.

- Improved Signal Integrity: Reduced crosstalk and optimized impedance for high-speed signals.

- Hybrid Configurations: Supports mixed power, single-ended, and differential signals in a single connector.

- Ruggedized Design: Ideal for harsh environment applications throughout aerospace and defense

Can R-VPX Evolution 2.0 VITA 46.30 connectors be used in existing VPX systems?

Yes, VITA 46.30 connectors are designed to be intermateable with VITA 46.0 connectors, meaning they can fit into the same slots. However, PCB designs must accommodate the smaller hole sizes required for high-speed signals.

What applications are best suited for R-VPX Evolution 2.0 VITA 46.30 connectors?

R-VPX Evolution 2.0 connectors are designed for use in harsh environment embedded systems. Common applications for these types of connectors include radar, avionics, secure communications, and other high-performance computing used throughout military and aerospace systems.

Do I need to redesign my backplane to use R-VPX Evolution 2.0 VITA 46.30 connectors?

While the connectors are mechanically compatible, the PCB must support the smaller hole sizes (as defined in the VITA 46.30 standard) for high-speed differential pairs. Power and single-ended signals can still use legacy hole sizes in hybrid configurations.

VITA 66.1 and 66.4 Connectors

What are VITA 66.1 and VITA 66.4 connectors?

VITA 66.1 and VITA 66.4 are VPX-compatible optical interconnect standards that use MT-style ferrules to enable high-density, blind-mate fiber optic connections between VPX modules and backplanes. VITA 66.1 defines a full-width format, while VITA 66.4 defines a half-width format to save space on the module.

What types of fibers do VITA 66.1 and 66.4 support?

VITA 66 optical interfaces are commonly implemented with singlemode or multimode fiber, depending on the system architecture and optical interface selection.

What key applications do VITA 66.1 and 66.4 connectors support?

VITA 66 connectors are utilized throughout high-speed, ruggedized embedded systems found in applications such as avionics, radar and electronic warfare systems, high-performance computing (HPC), data transmission in harsh environments, and more.

Are VITA 66.1 and 66.4 connectors interchangeable?

No, they have different mechanical footprints. VITA 66.1 is full-width, while VITA 66.4 is half-width.

What is the insertion loss and return loss performance of VITA 66 connectors?

Performance targets such as insertion loss and return loss depend on the specific optical interface and implementation. For exact values, refer to the applicable VITA standard requirements and the specific product datasheet.

Are VITA 66 connectors compatible with other VPX standards?

Yes, they are designed to work with VITA 46 (VPX) and VITA 65 (OpenVPX) backplanes. They can coexist with VITA 67 (RF coaxial) and VITA 66.5 (hybrid optical-electrical) connectors.

What environmental conditions do they support?

VITA 66 connectors are designed to operate in temperature ranges from -55 °C (-67 °F) to 85 °C (185 °F) (extended options available). They also meet MIL-STD-810 and VITA 47 standards for vibration and shock resistance, with sealed options available.

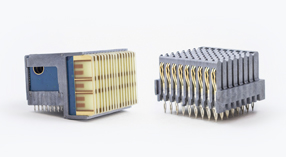

SpaceVPX VITA 78 Connectors

How does the VITA 78 connector ensure reliability in high-radiation space environments?

SpaceVPX is built around space-focused reliability requirements, including redundant connectivity defined by the VITA 78 specification. Amphenol SpaceVPX connectors also undergo space-relevant validation such as outgassing testing and system-representative vibration testing with BER monitoring.

What makes VITA 78 different from standard VPX connectors?

While based on OpenVPX, VITA 78 adds space-specific enhancements like dual-redundant pathways, higher vibration resistance, and radiation tolerance. It also complies with stricter fault-tolerance requirements for mission-critical systems.

Can VITA 78 connectors handle extreme thermal cycling in space?

Yes. Amphenol SpaceVPX connectors have been tested across an extreme temperature range of -55 °C to 105 °C, supporting repeated exposure to harsh thermal conditions associated with space hardware.

How does the dual-redundant connectivity work in VITA 78?

SpaceVPX implements dual redundancy through specific wafer loads defined by the VITA 78 specification, enabling redundant pathways to support continuous operation when redundancy is required by the system architecture.

Are VITA 78 connectors compatible with existing VPX backplanes?

While they share some mechanical and electrical traits with OpenVPX, VITA 78’s space-optimized features (like redundancy and radiation hardening) may require specific backplane designs. Hybrid systems need careful integration.

How do VITA 78 connectors address SWaP (Size, Weight, and Power) challenges in satellites?

The compact, modular design of Amphenol’s VITA 78 connectors reduces bulk while maintaining high-density connections. Lightweight materials and efficient power delivery help minimize system weight and energy consumption which is key for launch cost savings.

.jpg)

.jpg)

.jpg)